Statistical process control revolutionizes quality management through powerful visualization tools that monitor process stability over time. Among these tools, the I-MR chart stands as one of the most versatile and widely-used control charts in manufacturing, service industries, and continuous improvement initiatives.

This comprehensive guide explores how Individual Moving Range charts transform raw data into actionable insights for process optimisation.

Table of contents

Understanding I-MR Charts

An I-MR chart, also known as an Individual Moving Range chart or IMR chart, represents a dual-chart system that monitors both process location and variability simultaneously. The chart consists of two parts: the I-chart (Individuals chart) and the MR-chart (Moving Range chart), making it particularly effective for continuous data analysis.

What makes an I-chart unique compared to other control charts? They are particularly useful when data is collected one sample at a time, instead of in larger subgroups. This characteristic enables organizations to monitor processes where traditional sampling methods prove impractical or impossible.

The Individual Moving Range charts serves multiple critical functions in quality management systems. First, it tracks individual measurements over time, revealing trends and patterns that might otherwise remain hidden. Second, the moving range component estimates process variability, providing insights into consistency and predictability. Additionally, these charts identify special cause variations that require immediate attention and corrective action.

Statistical process control professionals rely on Individual Moving Range charts because they provide comprehensive process monitoring capabilities. Unlike other control charts that require multiple samples per subgroup, Individual Moving Range charts work effectively with single data points, making them ideal for various operational scenarios.

Public, Onsite, Virtual, and Online Six Sigma Certification Training!

- We are accredited by the IASSC.

- Live Public Training at 52 Sites.

- Live Virtual Training.

- Onsite Training (at your organization).

- Interactive Online (self-paced) training,

Key Components

Individual Chart (I-Chart) Component

The Individual chart plots actual measurement values in chronological order, creating a visual timeline of process performance. Each data point represents a single observation, measurement, or sample result from the monitored process. This component reveals process location trends, shifts, and unusual patterns that indicate potential quality issues.

Process engineers configure the I-chart with three essential lines: the centerline representing the process average, the upper control limit (UCL), and the lower control limit (LCL). These boundaries define the expected range of normal process variation based on historical data analysis.

The Individual chart component excels at detecting gradual process shifts, sudden changes in process mean, and cyclical patterns that might affect product quality. Furthermore, it provides immediate visual feedback about process performance, enabling rapid response to quality deviations.

Moving Range Chart (MR-Chart) Component

The moving range (MR) part of the chart estimates the variability within the process, complementing the location information provided by the Individual chart. The moving range calculates the absolute difference between consecutive measurements, creating a measure of short-term process variability.

Moving range calculations follow a straightforward formula: MR = |Xi – Xi-1|, where Xi represents the current measurement and Xi-1 represents the previous measurement. This calculation creates a series of range values that indicate how much the process varies from one measurement to the next.

The MR-chart component proves invaluable for detecting changes in process consistency and variability. When moving range values increase significantly, they indicate that process variation has increased, potentially signaling equipment wear, material changes, or procedural inconsistencies.

When to Use I-MR Charts?

Ideal Process Conditions for I-MR Implementation

I-MR control charts are used when the subgroup size is equal to 1, making them perfect for various operational contexts. Manufacturing processes that produce individual units, batch processes with single measurements, and service processes with periodic assessments all benefit from I-MR chart implementation.

Monthly reporting scenarios represent classic Individual Moving Range charts applications. Organizations monitor customer complaints, inventory levels, sales figures, and other key performance indicators using Individual Moving Range charts. These metrics typically cannot be grouped into traditional subgroups, making I-MR charts the optimal monitoring solution.

Laboratory testing environments frequently employ I-MR charts for individual test results, especially when testing costs or time constraints prevent multiple samples per time period. Similarly, automated manufacturing systems that collect continuous data streams benefit from Individual Moving Range charts monitoring capabilities.

Process Types Best Suited for I-MR Analysis

Continuous manufacturing processes with individual unit measurements work exceptionally well with I-MR charts. Examples include chemical batch processing, pharmaceutical manufacturing, food production, and electronics assembly where each unit receives individual quality assessment.

Service industry applications include call center response times, delivery performance metrics, customer satisfaction scores, and financial performance indicators. These processes generate individual data points that require monitoring for trends and unusual variations.

Administrative processes benefit significantly from I-MR chart implementation. Document processing times, approval cycle durations, and error rates all represent individual measurements that I-MR charts can monitor effectively.

Also Read: What is Statistical Process Control (SPC) Chart?

Creating Effective I-MR Charts

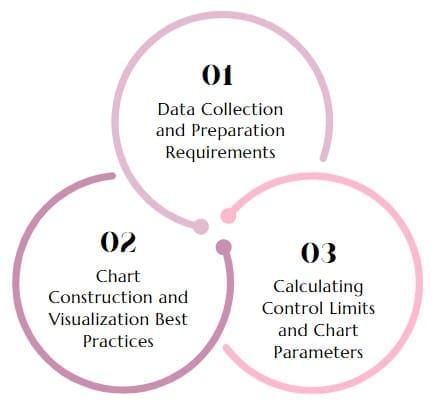

Data Collection and Preparation Requirements

Successful I-MR chart implementation begins with proper data collection planning and execution. Establish consistent measurement procedures, standardized sampling intervals, and reliable data recording systems. These foundational elements ensure accurate and meaningful chart results.

Data quality directly impacts I-MR chart effectiveness. Implement measurement system analysis procedures to verify gauge repeatability and reproducibility. Additionally, establish clear operational definitions for measured characteristics to eliminate measurement ambiguity and interpretation errors.

Determine appropriate sampling frequencies based on process characteristics and business requirements. High-frequency measurements provide detailed process insights but may consume excessive resources. Conversely, infrequent measurements might miss important process changes and variations.

Calculating Control Limits and Chart Parameters

Control limit calculations form the mathematical foundation of effective I-MR charts. The Individual chart centerline equals the average of all individual measurements: X̄ = ΣXi/n, where n represents the total number of observations.

Individual chart control limits use the average moving range for calculation. The upper control limit equals X̄ + 2.66(MR̄), while the lower control limit equals X̄ – 2.66(MR̄). The constant 2.66 represents the standard factor for Individual charts with moving ranges of size 2.

Moving range chart calculations follow similar principles. The MR chart centerline equals MR̄, the average of all moving range values. The upper control limit for the moving range chart equals 3.267(MR̄), while the lower control limit typically equals zero since moving ranges cannot be negative.

Chart Construction and Visualization Best Practices

Professional I-MR chart construction requires attention to visual clarity and interpretability. Use consistent scaling, appropriate time intervals, and clear labeling to ensure stakeholder understanding. Additionally, implement color coding systems that highlight control limits, centerlines, and out-of-control conditions.

Chart layout should facilitate easy interpretation and analysis. Position the Individual chart above the Moving Range chart, maintaining consistent time scales across both charts. This arrangement enables simultaneous analysis of location and variability patterns.

Software tools like Minitab, JMP, and Excel provide automated Individual Moving Range charts creation capabilities. These tools calculate control limits automatically, apply statistical rules, and generate professional-quality charts suitable for presentations and documentation.

Interpreting Individual Moving Range charts Patterns and Signals

Recognizing Out-of-Control Conditions

I-MR charts employ multiple statistical rules to identify out-of-control conditions that indicate special cause variations. The primary rule identifies points outside control limits on either the Individual or Moving Range chart. These points require immediate investigation and corrective action.

Additional pattern recognition rules enhance I-MR chart sensitivity to process changes. Seven consecutive points on one side of the centerline indicate a process shift. Similarly, seven consecutive increasing or decreasing points suggest a process trend requiring attention.

Cyclical patterns, unusual clustering, and systematic variations all represent special cause conditions that I-MR charts can detect. These patterns often indicate equipment issues, operator changes, material variations, or environmental influences affecting process performance.

Process Capability Assessment Using I-MR Data

This can be compared against specification limits to assess if the process is capable of consistently meeting requirements. Process capability analysis combines I-MR chart data with customer specifications to evaluate process performance adequacy.

Capability indices like Cp, Cpk, Pp, and Ppk quantify process performance relative to specification limits. These metrics help organizations understand whether their processes consistently meet customer requirements and identify improvement opportunities.

Long-term process capability assessment requires stable I-MR chart data collected over extended periods. Unstable processes with frequent out-of-control conditions cannot provide reliable capability estimates, emphasizing the importance of achieving statistical control first.

Also Read: What is Process Behaviour Chart?

Advanced I-MR Chart Applications and Techniques

Integrating I-MR Charts with Lean Six Sigma Methodologies

Lean Six Sigma projects extensively utilize Individual Moving Range charts throughout DMAIC (Define, Measure, Analyze, Improve, Control) methodology phases. During the Measure phase, I-MR charts establish baseline process performance and identify improvement opportunities.

The Analyze phase employs I-MR charts to investigate root causes of process variations and validate improvement hypotheses. Process changes implemented during the Improve phase require I-MR chart monitoring to verify effectiveness and sustainability.

Control phase activities rely heavily on I-MR charts for ongoing process monitoring and continuous improvement. These charts provide early warning signals for process degradation and help maintain improvement gains over time.

Software Implementation and Automation

Modern statistical software packages provide sophisticated Individual Moving Range charts capabilities that automate calculations, apply statistical rules, and generate professional reports. Minitab Individual Moving Range chart functions include automated control limit calculations, pattern recognition, and capability analysis integration.

JMP control chart features offer interactive visualization, real-time updates, and advanced statistical analysis capabilities. These tools enable process engineers to create comprehensive monitoring systems that support continuous improvement initiatives.

Excel-based Individual Moving Range chartsolutions provide accessible alternatives for organizations with limited statistical software budgets. Template-based approaches enable consistent chart creation while maintaining calculation accuracy and visual standards.

Best Practices for I-MR Chart Success

Establishing Robust Data Collection Systems

Effective I-MR chart implementation requires systematic data collection procedures that ensure accuracy, consistency, and timeliness. Develop standardized measurement protocols, calibration schedules, and data validation procedures to maintain chart reliability.

Training programs for data collectors and chart interpreters enhance I-MR chart effectiveness. Ensure personnel understand measurement procedures, statistical concepts, and appropriate response actions for out-of-control conditions.

Data management systems should support automated data collection, real-time chart updates, and historical data analysis. These capabilities enable proactive process monitoring and rapid response to quality issues.

Continuous Improvement Integration

I-MR charts serve as foundational tools for continuous improvement initiatives that drive operational excellence. Regular chart reviews, trend analysis, and process capability assessments identify improvement opportunities and guide resource allocation decisions.

Establish formal review cycles for Individual Moving Range chart analysis, including daily operational reviews, weekly trend assessments, and monthly performance evaluations. These structured approaches ensure consistent attention to process performance and improvement opportunities.

Integration with other quality tools enhances Individual Moving Range chart value. Combine chart analysis with root cause analysis, design of experiments, and process optimization techniques to maximize improvement results.

Common Mistakes and How to Avoid Them

Data Collection Pitfalls

Inconsistent measurement procedures represent the most common source of Individual Moving Range chart problems. Establish clear operational definitions, standardized measurement methods, and regular calibration schedules to maintain data quality.

Inappropriate sampling frequencies can mask important process variations or create unnecessary noise in chart interpretation. Balance measurement costs against information value to optimize sampling strategies.

Missing data points and irregular sampling intervals compromise I-MR chart effectiveness. Implement robust data collection systems that minimize gaps and maintain consistent time intervals between measurements.

Interpretation and Response Errors

Over-reaction to common cause variation wastes resources and may actually increase process variation. Train personnel to distinguish between special cause and common cause variations, responding appropriately to each situation.

Ignoring out-of-control signals allows process problems to persist and potentially worsen. Establish clear escalation procedures and response protocols for various out-of-control conditions.

Failure to investigate moving range chart signals often overlooks important process variability changes. Monitor both Individual and Moving Range charts simultaneously for comprehensive process understanding.

Also Read: Six Sigma Control Chart

Future in Digital Manufacturing

Industry 4.0 Integration Opportunities

Digital transformation initiatives create unprecedented opportunities for I-MR chart integration with automated manufacturing systems. Real-time data collection, automated chart generation, and intelligent alarm systems enhance traditional Individual Moving Range chart capabilities.

Internet of Things (IoT) sensors provide continuous data streams that enable high-frequency I-MR chart monitoring. These systems detect process changes rapidly and trigger automatic corrective actions when appropriate.

Machine learning algorithms can enhance Individual Moving Range chart interpretation by identifying subtle patterns and predicting potential process problems before they occur. These capabilities transform reactive quality control into proactive process optimization.

Emerging Technologies and Applications

Cloud-based statistical process control platforms enable remote I-MR chart monitoring and collaborative analysis across global manufacturing networks. These systems provide centralized visibility and standardized analysis procedures.

Mobile applications bring Individual Moving Range chart capabilities to shop floor personnel, enabling real-time process monitoring and immediate response to quality issues. These tools democratize statistical process control and improve organizational quality culture.

Artificial intelligence integration promises to revolutionize I-MR chart applications through automated pattern recognition, predictive analytics, and intelligent process optimization recommendations.

Frequently Asked Questions About I-MR Charts

What is an I-MR chart and how does it differ from other control charts?

An I-MR chart (Individual Moving Range chart) is a statistical process control tool that monitors individual measurements and their variability over time. Unlike other control charts that use subgroups of multiple samples, I-MR charts work with single data points, making them ideal for processes where individual measurements are collected rather than sample groups.

When using an I and MR chart, MR refers to which one of the following terms?

MR refers to “Moving Range,” which represents the absolute difference between consecutive individual measurements in the data sequence. The moving range component estimates short-term process variability and helps detect changes in process consistency over time.

How do you calculate control limits for I-MR charts?

For the Individual chart, control limits use the formula: UCL = X̄ + 2.66(MR̄) and LCL = X̄ – 2.66(MR̄), where X̄ is the average of individual measurements and MR̄ is the average moving range. For the Moving Range chart, UCL = 3.267(MR̄) and LCL = 0 (since moving ranges cannot be negative).

How can I create Individual Moving Range charts using Minitab or other statistical software?

Most statistical software packages, including Minitab, JMP, and specialized Six Sigma tools, provide built-in I-MR chart functions. These tools automatically calculate control limits, apply statistical rules for out-of-control detection, and generate professional-quality charts suitable for analysis and presentation.

How do you interpret out-of-control signals on Individual Moving Range charts?

Out-of-control signals include points beyond control limits on either chart, seven consecutive points on one side of the centerline, seven consecutive increasing or decreasing points, cyclical patterns, and unusual clustering. Each signal type indicates different process conditions requiring specific investigation and corrective action approaches.