Table of contents

Estimated reading time: 4 minutes

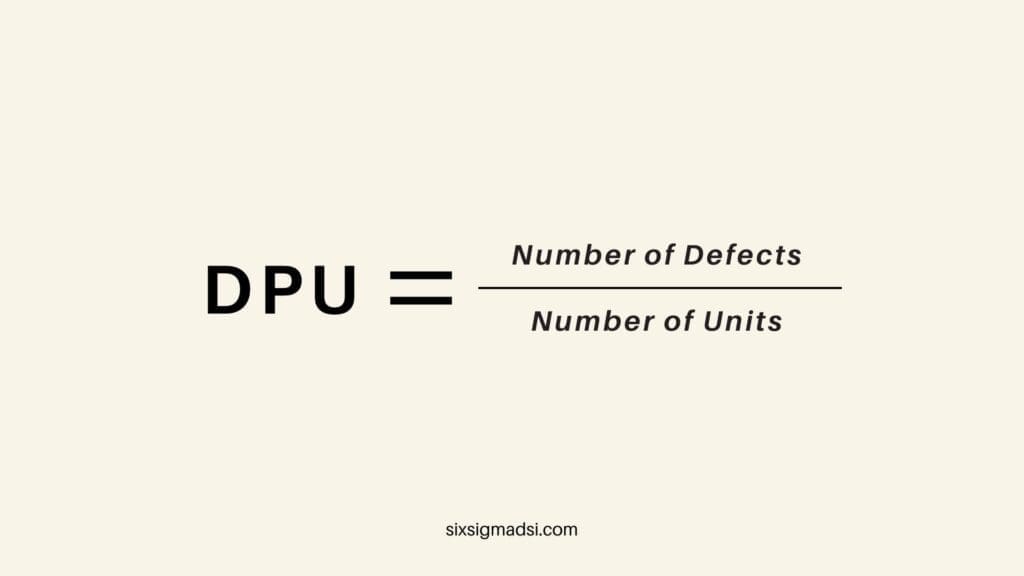

What are Defects Per Unit (DPU)?

Defects per Unit (DPU) is a measure of process quality in Six Sigma that is used to identify and track the number of defects in a process. It is calculated by dividing the total number of defects in a process by the total number of units produced.

DPU = (Number of Defects) / (Number of Units Produced)

Defects per Unit are used to determine the number of defects present in each unit produced. It measures the average number of defects in the units produced. A lower DPU value indicates a higher quality process with fewer defects per unit.

DPU is a useful metric to track and monitor process quality, as it can help organizations identify areas of the process that need improvement and to track progress over time. By reducing the number of defects per unit, organizations can increase efficiency, reduce costs, and improve customer satisfaction.

DPU also calculates the process sigma level, which measures process capability. The higher the sigma level, the better the process capability and fewer defects per unit.

Benefits of Attending to DPU

Attending to defects per unit (DPU) and actively managing and reducing defects can offer several benefits to organizations. Here are some of the key advantages:

- Improved Product Quality:

- By addressing and reducing defects per unit, organizations can enhance the overall quality of their products or services. This can lead to increased customer satisfaction and loyalty.

- Cost Savings:

- Fewer defects mean less rework, repair, or replacement costs. Organizations can save money by minimizing the resources spent on addressing issues and improving the efficiency of their processes.

- Enhanced Reputation:

- Consistently delivering high-quality products can contribute to a positive reputation in the market. Customers are more likely to trust and choose products from companies known for their commitment to quality.

- Increased Customer Satisfaction:

- Lower defects per unit typically result in products that meet or exceed customer expectations. This leads to higher satisfaction levels among customers, which can translate into repeat business and positive word-of-mouth referrals.

- Operational Efficiency:

- Focusing on defects per unit encourages organizations to identify and eliminate inefficiencies in their processes. This can lead to streamlined operations and improved productivity.

- Compliance and Standards:

- Meeting or exceeding quality standards and compliance requirements is essential for many industries. Managing defects per unit helps organizations ensure that their products adhere to regulatory standards, reducing the risk of legal or compliance issues.

- Competitive Advantage:

- Organizations that consistently produce high-quality products may gain a competitive edge in the market. A reputation for quality can be a differentiating factor that attracts customers and sets a company apart from its competitors.

- Continuous Improvement:

- Tracking defects per unit is a fundamental part of a continuous improvement process. By regularly monitoring and analyzing these metrics, organizations can identify trends, root causes, and areas for improvement, leading to ongoing enhancements in processes and products.

- Data-Driven Decision Making:

- DPU metrics provide data that can be used for informed decision-making. Organizations can use this data to identify patterns, make strategic decisions, and allocate resources more effectively.

- Employee Morale:

- A focus on quality improvement can positively impact employee morale. When employees see their efforts contributing to higher product quality and customer satisfaction, it can boost their job satisfaction and motivation.

Why is DPU Important?

It is essential because it measures the quality of a process and helps organizations identify areas of the process that need improvement. It can track the number of defects per unit produced and measure the effectiveness of process improvements over time. Organizations can increase efficiency, reduce costs, and improve customer satisfaction by reducing the number of defects per unit.

It is also important because it can be used as a key performance indicator (KPI) for organizations to track and monitor process quality. It can help organizations to identify patterns and trends in the data and identify areas of the process that need improvement.

Furthermore, it is a widely accepted and widely used metric in Six Sigma, as it is a simple and easy-to-understand metric that can be used to track the quality of a process. This makes it easy for organizations to communicate process quality to stakeholders, including customers, employees, and management.

In summary, DPU is essential because it is a measure of the quality of a process, helps to identify areas of the process that need improvement, can be used as a KPI, is used to calculate the sigma level, and is widely accepted and used in Six Sigma, and easy to understand and communicate to stakeholders.