Table of contents

Estimated reading time: 4 minutes

What is the Cost of Non-Conformance?

In the dynamic landscape of business and quality management, the term “Cost of Non-Conformance” holds paramount importance. It serves as a crucial metric for organizations striving to enhance efficiency, minimize risks, and optimize their operations. In this blog, we will delve into the intricacies of the Cost of Non-Conformance, exploring its definition, components, impact on businesses, and strategies for mitigation.

The Cost of Non-Conformance refers to the financial implications incurred by an organization due to failure to meet quality standards or compliance requirements. This cost encompasses both tangible and intangible expenses, ultimately affecting the overall performance and reputation of a company.

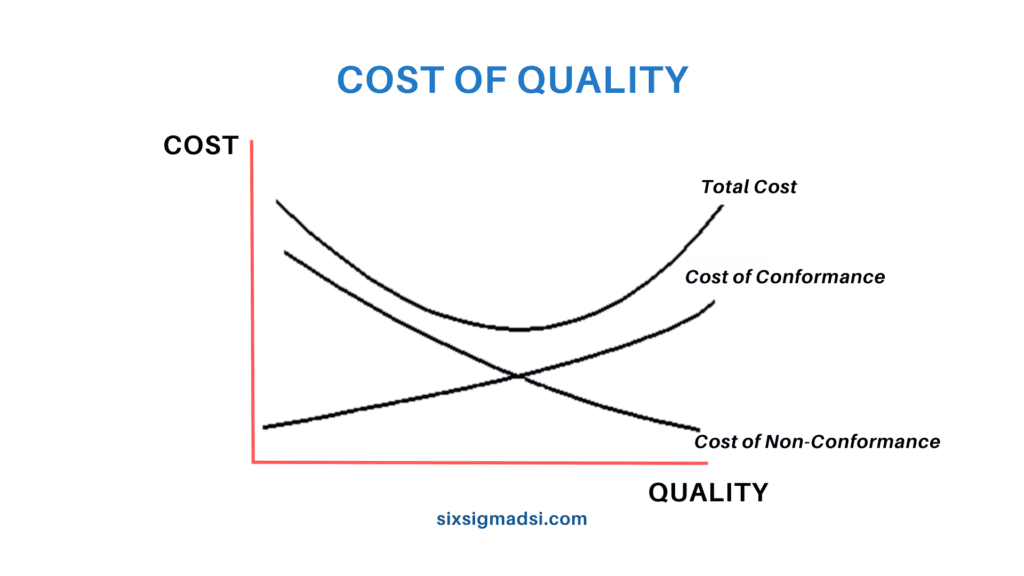

Cost of Non-Conformance is when a product, or process, fails to meet a set standard of quality. CONC is one factor that adds up to the Cost Of Quality (COQ) of a product, while the other is the Cost of Conformance (COC).

COC is the total cost of achieving a certain quality level for a product/service. CONC, however, refers only to costs that are incurred to correct an error. Non-conformance may occur at any stage of the product’s lifecycle. This includes during manufacturing and poor quality audits. This can lead to both internal failure costs and external failure costs. These are costs that were identified in the development phase and prior to a product being released. These could include:

- Downtime is the loss of hours due to a system failure, or poor organization.

- Scrap: A cost for a product that is defective and cannot be repaired or replaced.

After receiving the product, the customer will identify external failure costs. These could include:

- Remember: If the manufacturer discovers that a product is defective, it will cost to return or exchange it.

- Warranty Claims: This is the cost of repair or replacement if a product breaks down within a certain time frame.

Adopting Six Sigma principles can help reduce non-conformance rates and costs. This will result in increased productivity and customer satisfaction.

According to the overall COQ model, an initial investment in quality can lower spending and result in higher profits down the road. Process improvements can improve employee morale, and brand credibility, and create a positive working environment. A company can optimize its quality system and performance standards by understanding what non-conformances mean and how they are measured.

Project managers must find the right balance between compliance costs and acceptable failure costs.

Types of Non-Conformance Costs

- Prevention Costs: These are expenses associated with activities aimed at preventing defects or non-compliance issues before they occur. Examples include training programs, quality control measures, and process improvements.

- Appraisal Costs: involve activities that assess and evaluate products or processes to ensure compliance with quality standards. This includes inspections, testing, and audits.

- Internal Failure Costs: Internal failure costs arise when defects are identified before products reach customers. Examples include rework, scrap, and downtime due to production interruptions.

- External Failure Costs: These costs occur when defects or non-compliance issues are discovered by customers. External failure costs encompass warranty claims, product recalls, customer complaints, and damage to reputation.

Impact on Business

- Financial Consequences: The direct financial impact of non-conformance costs can be substantial, affecting profitability and operational sustainability.

- Reputational Damage: Non-conformance incidents can tarnish a company’s reputation, leading to loss of customer trust and loyalty.

- Legal and Regulatory Consequences: Failure to meet quality standards or compliance requirements may result in legal actions, regulatory fines, and sanctions.

Calculating the Cost of Non-Conformance

- Identifying Costs: Thoroughly analyze prevention, appraisal, internal failure, and external failure costs to get a comprehensive understanding.

- Quantifying Costs: Assign monetary values to each cost component, ensuring an accurate representation of the financial impact.

- Continuous Monitoring: Establish a robust system for ongoing monitoring and measurement of non-conformance costs to identify trends and areas for improvement.

Mitigation Strategies

- Implement Robust Quality Management Systems: Develop and implement effective quality management systems to prevent defects and ensure compliance from the outset.

- Continuous Improvement: Foster a culture of continuous improvement, encouraging employees to identify and address potential non-conformance issues proactively.

- Training and Skill Development: Invest in employee training and skill development programs to enhance competencies and reduce the likelihood of errors.

Conclusion

The Cost of Non-Conformance is a critical metric that organizations cannot afford to overlook. By understanding its components, and impact, and implementing effective mitigation strategies, businesses can strive towards achieving higher quality, increased customer satisfaction, and sustained success in today’s competitive market.