Lean daily management represents a systematic approach to managing day-to-day operations effectively. This methodology focuses on creating structured daily processes that align with strategic objectives. Moreover, lean daily management integrates continuous improvement into routine operational activities.

Organizations implement lean daily management to bridge the gap between strategy and execution. Furthermore, this approach ensures consistent performance monitoring and rapid problem resolution. Daily management systems create accountability while empowering teams to drive improvements independently.

The core principle involves establishing predictable daily rhythms that support organizational goals. Additionally, lean daily management promotes visual management techniques for enhanced transparency. Therefore, teams can quickly identify issues and implement corrective actions.

Table of contents

Understanding Daily Management Systems (DMS)

A daily management system serves as the operational backbone for lean organizations. These systems coordinate various management activities through structured daily processes. Moreover, DMS creates consistent frameworks for performance monitoring and improvement initiatives.

Daily management systems integrate multiple components including visual boards, standard processes, and engagement protocols. Each component supports specific aspects of operational excellence. Consequently, organizations achieve better alignment between strategic goals and daily activities.

Public, Onsite, Virtual, and Online Six Sigma Certification Training!

- We are accredited by the IASSC.

- Live Public Training at 52 Sites.

- Live Virtual Training.

- Onsite Training (at your organization).

- Interactive Online (self-paced) training,

What is Lean Daily Management?

Lean Daily Management is a structured approach to managing daily tasks. It stems from lean principles, emphasizing waste reduction and continuous improvement. LDM involves daily direction setting, team engagement, and performance tracking. It uses tools like daily management boards to visualize progress and address issues quickly.

Unlike traditional management, LDM promotes real-time problem-solving. It ensures teams stay aligned with strategic goals. By fostering accountability, LDM drives operational excellence across industries.

Why Lean Daily Management Matters?

LDM enhances efficiency and team collaboration. It empowers employees to address issues promptly. By focusing on daily processes, businesses can achieve:

- Improved Productivity: Streamlined tasks reduce wasted time.

- Better Quality: Consistent processes enhance output quality.

- Employee Engagement: Teams feel empowered to contribute ideas.

- Alignment with Goals: Daily tasks support long-term objectives.

For example, a daily management system in healthcare can reduce patient wait times. In manufacturing, it minimizes production delays.

Components of Lean Daily Management Board

Visual Management Elements

Lean daily management boards serve as central communication hubs for teams. These boards display critical information including performance metrics, improvement projects, and daily priorities. Moreover, visual management creates transparency that enables rapid decision-making.

Effective daily management boards incorporate multiple information categories:

- Performance Metrics track key operational indicators against targets. Safety, quality, delivery, and cost metrics typically receive prominent display. Color coding helps teams quickly assess performance status.

- Problem-Solving Activities showcase current improvement initiatives and their progress. This section maintains focus on continuous improvement while celebrating successes.

- Communication Updates share important information affecting daily operations. Shift changes, equipment status, and customer requirements receive regular updates.

How to Implement a Lean Daily Management System?

Implementing LDM requires planning and commitment. Follow these steps to create an effective daily management system:

1. Define Objectives

Start by identifying key performance indicators (KPIs). These metrics align with your business goals. For instance, a factory might track production output or defect rates. Clear objectives guide the LDM process.

2. Create a Daily Management Board

A lean daily management board visualizes performance data. It includes KPIs, action items, and progress updates. Design the board for clarity, using charts or color-coded indicators. Place it in a central location for team access.

3. Establish Daily Huddles

Hold short, focused meetings daily. Discuss progress, challenges, and action plans. Keep huddles under 15 minutes to maintain efficiency. Encourage team input to foster engagement.

4. Standardize Processes

Develop standard work procedures for consistency. Document tasks like machine setup or patient check-ins. Standardization reduces errors and ensures repeatable results.

5. Monitor and Improve

Track KPIs daily using the management board. Identify trends or issues early. Use root cause analysis to address problems and implement improvements.

For a step-by-step guide, explore our daily work management steps.

Also See: Lean Certification

Lean Daily Management Board Examples

Daily management boards vary by industry. Here are practical examples:

Manufacturing

A factory’s LDM board tracks production rates and downtime. It includes a section for safety incidents. Teams review the board daily to address bottlenecks.

Healthcare

A hospital’s daily management system board monitors patient flow. It tracks wait times and staff availability. Daily huddles ensure timely adjustments to schedules.

Retail

A retail store’s board focuses on sales targets and inventory levels. It highlights customer feedback and staffing needs. This helps managers optimize operations.

Lean Management Quadrant Approach

The lean management quadrant organizes daily management activities into four primary categories. This framework helps leaders balance various management responsibilities effectively. Additionally, it provides structure for comprehensive operational oversight.

Strategy Deployment Quadrant

This quadrant focuses on translating strategic objectives into daily operational activities. Leaders ensure alignment between long-term goals and immediate priorities. Furthermore, this area emphasizes progress monitoring and course correction.

Daily Operations Management Quadrant

Operational management activities receive attention in this quadrant. Performance monitoring, problem resolution, and resource allocation occur here. Moreover, this quadrant ensures consistent operational execution.

Improvement Management Quadrant

Continuous improvement initiatives fall within this quadrant’s scope. Teams identify opportunities, implement solutions, and measure results. Additionally, this area promotes innovation and operational excellence.

People Development Quadrant

Team development and capability building receive focus in this quadrant. Training, coaching, and skill development support long-term organizational success. Furthermore, people development ensures sustainable improvement capabilities.

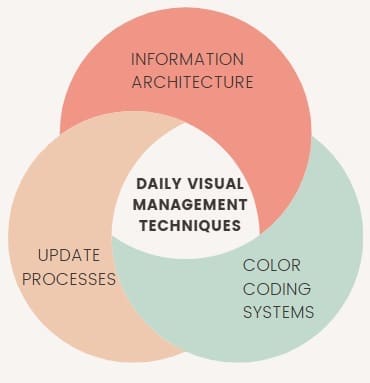

Daily Visual Management Techniques

Information Architecture

Effective daily visual management requires thoughtful information architecture. Displays must prioritize critical information while remaining easily understood. Moreover, visual hierarchy guides attention to the most important elements.

Information architecture should reflect team needs and decision-making requirements. Additionally, it must accommodate different skill levels and backgrounds.

Color Coding Systems

Consistent color coding enhances visual communication effectiveness. Red, yellow, and green indicators provide immediate status recognition. Furthermore, standardized color schemes reduce interpretation time and errors.

Color coding systems should accommodate color-blind team members through additional visual cues. Additionally, they must remain consistent across different display types.

Update Processes

Regular update processes maintain visual management accuracy and relevance. Designated responsibilities ensure timely information refresh. Moreover, update processes should integrate seamlessly with daily workflows.

Automated data feeds reduce manual update requirements where possible. Additionally, backup procedures ensure continuity during system disruptions.

Also Read: What is Lean Thinking?

Tools for Lean Daily Management

Several tools support LDM implementation:

- Daily Management Boards: Physical or digital boards for tracking KPIs.

- Software Solutions: Tools like Trello or Asana visualize daily tasks.

- Visual Management Systems: Charts and dashboards for real-time data.

- Lean Training Programs: Resources to educate teams on LDM principles.

Digital tools enhance accessibility, especially for remote teams. For instance, a daily management system in healthcare might use software to track patient metrics.

Benefits of Lean Daily Management

LDM offers significant advantages for businesses:

- Real-Time Insights: Daily tracking identifies issues quickly.

- Team Accountability: Employees take ownership of tasks.

- Reduced Waste: Lean principles eliminate inefficiencies.

- Enhanced Communication: Daily huddles improve collaboration.

By adopting LDM, businesses can execute on strategy effectively.

Lean Daily Management in Different Industries

LDM adapts to various sectors, delivering tailored benefits.

Healthcare

In healthcare, LDM streamlines patient care processes. Daily management system boards track bed occupancy and staff performance. This reduces delays and improves patient satisfaction.

Manufacturing

Manufacturers use LDM to monitor production lines. Daily huddles address equipment issues promptly. This minimizes downtime and boosts output.

Service Industry

Service businesses, like call centers, use LDM to track response times. Daily management boards highlight performance gaps, enabling quick fixes.

These examples show LDM’s versatility in managing daily improvement.

Common Challenges and Solutions

Implementing LDM can face obstacles. Here’s how to overcome them:

- Resistance to Change: Train teams on LDM benefits to gain buy-in.

- Data Overload: Focus on key metrics to avoid confusion.

- Inconsistent Huddles: Schedule meetings at the same time daily.

- Lack of Standardization: Document processes clearly for consistency.

Proper planning ensures a smooth LDM rollout.

Lean Daily Management vs. Traditional Management

Traditional management often focuses on long-term planning. It may overlook daily operations. LDM, however, emphasizes day-to-day management. It uses real-time data to drive immediate improvements. While traditional methods rely on periodic reviews, LDM ensures continuous progress through daily engagement systems.

For instance, a lean management quadrant divides tasks into urgent and important. LDM prioritizes daily tasks to align with strategic goals. This proactive approach sets LDM apart.

Tips for Sustaining Lean Daily Management

To maintain an effective LDM system:

- Train Regularly: Educate teams on lean principles and tools.

- Update Boards: Refresh KPIs to reflect current goals.

- Engage Employees: Involve staff in problem-solving discussions.

- Review Progress: Assess LDM effectiveness monthly.

Frequently Asked Questions (FAQ) on Lean Daily Management

What is the difference between daily management and traditional management approaches?

Daily management focuses on structured daily processes for continuous improvement, while traditional management typically addresses issues reactively. Daily management integrates strategic alignment with operational execution.

How long does it take to implement a lean daily management system?

Implementation typically requires 3-6 months for basic systems, with full maturity taking 12-18 months. Success depends on organizational commitment, change management effectiveness, and system complexity.

Can daily management systems work in service industries?

Yes, daily management principles apply across all industries including healthcare, financial services, and retail. The key is adapting visual tools and metrics to industry-specific requirements.

What size organization benefits most from daily management systems?

Organizations of all sizes can benefit from daily management. Small companies often see faster implementation while larger organizations may require phased deployment approaches.

How do you maintain employee engagement with daily management boards?

Maintain engagement through regular content updates, employee involvement in board design, recognition of contributions, and clear connection between daily activities and organizational success.

What technology is required for daily management implementation?

Basic daily management requires minimal technology – primarily visual boards and simple tracking tools. Digital solutions can enhance capabilities but aren’t necessary for initial success.