The 5S methodology is a foundational component of Lean management, a systematic approach to improving efficiency, reducing waste, and optimizing productivity in the workplace.

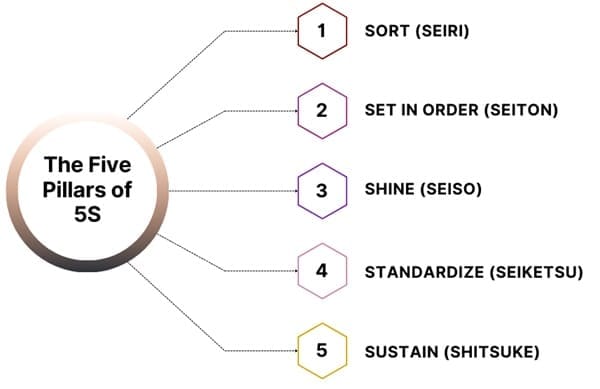

Originating from Japan, the 5S process is based on five principles: Sort, Set in Order, Shine, Standardize, and Sustain. These principles help create an organized, efficient, and safe work environment, which is crucial for maintaining high productivity and quality standards in any industry.

Table of contents

What is 5S in Lean?

5S is a fundamental part of Lean methodology, a systematic approach used to enhance workplace efficiency and eliminate waste. 5S represents five Japanese terms: Seiri (Sort), Seiton (Set in Order), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain).

The Philosophy Behind 5S

5S is not merely about cleanliness; it is a philosophy that integrates organization and management of the workspace to streamline processes, eliminate inefficiencies, and foster a culture of continuous improvement.

The ultimate goal is to create a working environment that supports high productivity, safety, and quality, all while minimizing waste and variability in processes.

Types of Waste

To fully appreciate the impact of 5S, it is essential to understand the three types of waste in Lean methodology: Muri, Mura, and Muda.

- Muri refers to overburden or unreasonableness in work processes. It occurs when employees or machines are pushed beyond their limits, leading to inefficiencies and increased risk of errors or accidents.

- Mura means unevenness or inconsistency. It represents the variability in processes that can lead to inefficiencies, such as fluctuating workloads or inconsistent quality.

- Muda is waste or activities that do not add value to the product or service. Muda can manifest in various forms, such as overproduction, excess inventory, unnecessary transportation, waiting time, over-processing, motion, and defects.

The 5S approach directly addresses these wastes by creating a more organized and consistent work environment, ultimately reducing Muri, Mura, and Muda.

The Five Pillars of 5S

Importance of 5S in Lean Management

1. Sort (Seiri): Decluttering the Workspace

The first step in the 5S methodology is Sort (Seiri), which involves identifying and removing unnecessary items from the workspace. This process is crucial because clutter can obstruct workflow, create safety hazards, and reduce overall efficiency.

By sorting through tools, materials, and equipment, workers can identify what they truly need for current operations and remove or relocate the rest.

Red Tagging:

An essential tool in the Sort process is the use of red tags. We tag items that are not immediately recognized as essential with red labels, signalling the need for evaluation. The red tag shows that we may need to move, dispose of, recycle, or store the item elsewhere.

For example, if we haven’t used a tool for a long time, we place it in a “Red Tag Holding Area.” If no one uses the tool within a specified period, we consider it unnecessary and remove it from the workspace.

This systematic removal of non-essential items helps streamline operations and create a more efficient work environment.

2. Set in Order (Seiton): Organizing the Workspace

After you clear the workspace of unnecessary items, organize the remaining tools, materials, and equipment. This phase, known as Set in Order (Seiton), ensures that everything is stored in its designated place for easy access and return after use.

Standardization and Accessibility:

In the Set in Order phase, it’s crucial to establish a standardized method for storing and retrieving items. Frequently used tools should be placed close to the user, while less frequently used items can be stored further away.

For example, if certain tools are often used together, they should be stored together to minimize the time spent searching for them. Additionally, using labels and signs to mark storage locations helps maintain order and makes it easier for everyone, even those unfamiliar with the system, to find what they need.

Efficiency in Movement:

The organization of the workspace should minimize the need for bending, reaching, or excessive movement. Tools can be attached to retractable cords, for instance, allowing them to return automatically to their designated positions after use.

This reduces the risk of misplacing tools and ensures they are always readily available. The goal is to create a workspace where everything has its place, reducing time wasted searching for items and increasing overall productivity.

3. Shine (Seiso): Maintaining a Clean Workspace

Shine (Seiso) is the third step in the 5S methodology, focusing on cleanliness and maintenance. A clean work environment is essential for preventing accidents, maintaining equipment efficiency, and ensuring product quality. Regular cleaning routines help identify potential issues, such as leaks or wear and tear before they become major problems.

Daily Cleaning Routines:

Integrate cleaning into daily activities, rather than treating it as a separate task. Encourage workers to take responsibility for maintaining clean and tidy work areas.

For example, promptly clean oil stains, dust, or metal shavings around machinery to prevent accidents or equipment damage.

By maintaining a clean environment, workers can quickly identify and address any issues that could affect productivity or safety.

Bright and Well-Lit Workspaces:

To facilitate cleaning and inspection, factory floors are often painted in bright colours, and lighting is enhanced. This not only makes it easier to spot dirt and debris but also creates a more pleasant and safe working environment.

A clean workspace contributes to higher efficiency and morale, as workers can focus on their tasks without distractions or hazards.

4. Standardize (Seiketsu): Creating Consistent Procedures

Standardize (Seiketsu) establishes uniform procedures and standards to ensure consistent maintenance of the first three S’s—Sort, Set in Order, and Shine. This step involves creating clear guidelines for maintaining organization and cleanliness in the workplace.

Developing Standards:

Standards should be developed based on best practices and should be easy to understand and follow. These might include procedures for cleaning, labelling, and storing items. For example, a company might establish a routine where workers spend the last 10 minutes of their shift cleaning their workspace and returning tools to their designated spots.

Having clear standards ensures that everyone knows what is expected of them, reduces confusion, and keeps the workspace organized and efficient.

Visual Management:

Teams often use visual management tools, such as color-coded labels, signs, and charts, to reinforce standards. For example, they assign different colors to indicate various types of tools or materials, making it easy to quickly identify where everything belongs.

Managers place larger signs or banners around the workspace to remind employees of the 5S principles and encourage adherence to standards.

5. Sustain (Shitsuke): Maintaining and Improving the System

The final step in the 5S methodology is Sustain (Shitsuke), which focuses on maintaining and continuously improving the 5S system. This step is crucial for ensuring that the gains made through the previous steps are not lost over time.

Building a Culture of Discipline:

Sustaining the 5S system requires a culture of discipline and continuous improvement. We need to train employees on the importance of the 5S principles and encourage them to incorporate these principles into their daily routines. Regular training sessions and reminders can help keep 5S practices at the forefront of employees’ minds.

Routine Inspections:

A designated team should regularly conduct inspections to ensure the maintenance of 5S standards. They can use checklists and other tools to evaluate the workspace. The team can then use the inspection results to identify areas for improvement and celebrate successes.

Continuous Improvement:

The 5S system is not a one-time initiative but a continuous process. As the work environment and processes evolve, the 5S standards should be reviewed and updated as necessary. Encouraging employees to suggest improvements can help keep the system dynamic and responsive to changing needs.

Advantages of Implementing 5S in Lean Management

Implementing the 5S methodology in Lean management offers numerous benefits that can significantly improve workplace efficiency, safety, and productivity.

- Enhanced Productivity:

By organizing the workspace and removing unnecessary items, workers can perform their tasks more efficiently, leading to increased productivity. Time spent searching for tools or materials is minimized, allowing employees to focus on value-adding activities. - Improved Safety:

A well-organized and clean workspace reduces the risk of accidents and injuries. By following the 5S principles, companies can create a safer work environment, which is essential for protecting employees and maintaining high productivity levels. - Reduced Waste:

The 5S methodology helps identify and eliminate waste, such as unnecessary materials, excess inventory, and inefficient processes. This leads to cost savings and more efficient use of resources. - Higher Quality:

A clean and organized workspace helps ensure that tools and equipment are in good condition, reducing the likelihood of defects or rework. By maintaining high standards of cleanliness and organization, companies can produce higher-quality products. - Employee Engagement:

Involving employees in the 5S process can increase their sense of ownership and responsibility for their work environment. This can lead to higher job satisfaction, better teamwork, and a more positive workplace culture. - Sustainability:

The 5S methodology promotes sustainable practices by encouraging the efficient use of resources and reducing waste. This can contribute to a company’s overall sustainability goals and improve its reputation with customers and stakeholders. - Continuous Improvement:

By embedding the 5S principles into the company culture, organizations can create a mindset of continuous improvement. This ensures regular review and updating of processes and standards to keep pace with changes in the business environment.

Final Words

The 5S methodology is a powerful tool in Lean management that helps organizations create a more efficient, safe, and productive work environment. By following the five principles of Sort, Set in Order, Shine, Standardize, and Sustain, companies can streamline operations, reduce waste, and improve overall performance.

The benefits of implementing 5S go beyond just organizing the workspace; they extend to enhancing employee morale, improving product quality, and fostering a culture of continuous improvement.

About Six Sigma Development Solutions, Inc.

Six Sigma Development Solutions, Inc. offers onsite, public, and virtual Lean Six Sigma certification training. We are an Accredited Training Organization by the IASSC (International Association of Six Sigma Certification). We offer Lean Six Sigma Green Belt, Black Belt, and Yellow Belt, as well as LEAN certifications.

Book a Call and Let us know how we can help meet your training needs.