Table of contents

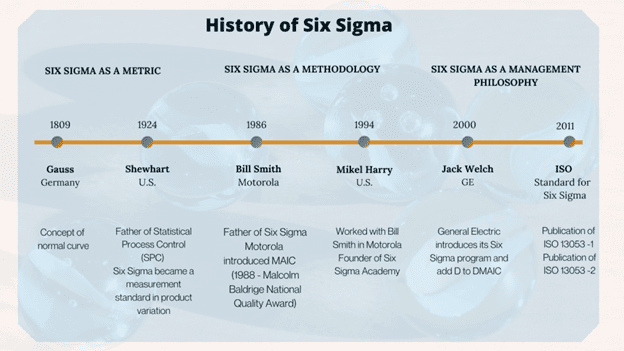

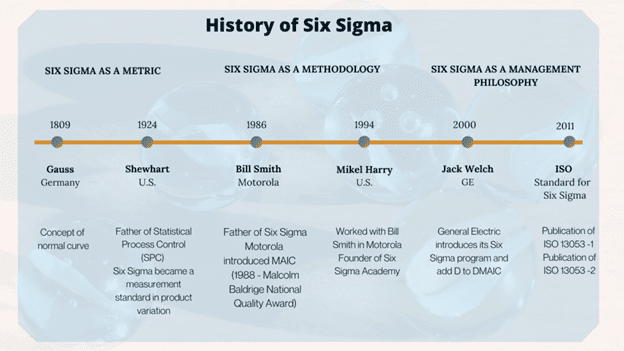

Brief History of Six Sigma

Few people know the brief history of Lean Six Sigma, but when a business is struggling, Six Sigma is a very sought-after powerful tool that can improve processes. Companies are looking for Six Sigma Belts, which are individuals who have been trained in all or part of Six Sigma, to help them improve their business performance.

Created by Bill Smith

Six Sigma was created by Bill Smith in the 1980s, as the 80s were ending. He was working at Motorola at the time and needed a quality management tool to increase business performance. He set about developing the method and spent all of his energy on what would be the future of quality management. Smith was supported by Bob Galvin (the CEO at Motorola), which made his job easier.

Motorola applied the method companywide after Smith was done. Motorola was awarded the Malcolm Baldrige National Quality Award in 1988 for its new process management tool. This award is given to organizations that have demonstrated operational excellence in a variety of sectors.

Jack Welch made Six Sigma famous

In the 1990s Jack Welch (the chairman of General Electric) adopted Six Sigma in his company. The company developed the method and linked it to executive compensation and return on investment (ROI). In GE’s annual reports, they showed that Six Sigma implementation had financial benefits. To improve their business operations, corporations on the Forbes Fortune 500 list began to implement Six Sigma. Jack Welch said, “Six Sigma changed the DNA of GE.”

The synergy between LEAN and Six Sigma

Six Sigma draws inspiration from LEAN, a quality management method. Although it might seem like Six Sigma and LEAN could be considered rivals, they are complementary. Combining the two can produce unmatched business performance benefits, known as Lean Six Sigma. LEAN is a hands-on approach that removes non-value-adding tasks and improves efficiency. Six Sigma aims to decrease variability in organizational processes to minimize the likelihood of defects.

LEAN has been around longer than Six Sigma, and its roots are in Japan’s Toyota Production System (TPS), which was established in the 60s. LEAN thinking is also rooted in the Arsenal of Venice, which was established in the 1450s. Henry Ford, who fully implemented LEAN thinking in his business operations, was the first to apply it to practice it.

Boeing adopted Six Sigma in 1993

Boeing adopted Six Signa in its 1993 manufacturing process. This made it even more popular. Boeing continued to invest in the method until it was successful, even though its initial attempts were unsuccessful.

Six Sigma is still a new concept in business. Many companies around the globe are still trying to improve Six Sigma to improve their business efficiency through process improvement. Six Sigma and Lean, which were recently revived, have made a lasting impression on history.