A 5S Event is a structured, short-term activity. During this event, teams come together to apply the five principles of 5S—Sort, Set in Order, Shine, Standardize, and Sustain—to a designated workspace. These events typically last three to five days. Their primary aim is to achieve significant improvements in organization and efficiency within a condensed timeframe.

Table of contents

What is a 5S Event?

A 5S event is a focused and collaborative activity where we apply the 5S methodology to a specific area or process within an organization. Think of it as a short, intense burst of improvement aimed at creating a more organized, efficient, and safer workspace.

We don’t just talk about making things better; we actively do it, following the five steps of 5S: Sort, Set in Order, Shine, Standardize, and Sustain.

Imagine a team overwhelmed by clutter in their shared workspace. Tools are misplaced, documents are piled high, and it’s difficult to find anything quickly.

A 5S event provides a structured way for this team to tackle the chaos head-on. Over a period of typically a few days, they work together to systematically go through everything in their area, eliminate what’s unnecessary, arrange what remains logically, clean thoroughly, establish clear standards, and create habits to maintain the improvements.

Public, Onsite, Virtual, and Online Six Sigma Certification Training!

- We are accredited by the IASSC.

- Live Public Training at 52 Sites.

- Live Virtual Training.

- Onsite Training (at your organization).

- Interactive Online (self-paced) training,

Five Pillars of a 5S Event

A 5S event revolves around the active application of its five core principles. Let’s delve into each of these “S” words and understand what actions they involve during an event:

1. Sort (Seiri): We Eliminate the Unnecessary

During the Sort phase of a 5S event, we critically evaluate every item in the target area. We ask ourselves: “Is this truly needed here, right now?” Our goal is to remove anything that is unnecessary for the immediate work. This includes:

- Obsolete items: Broken tools, outdated materials, old paperwork that no longer serves a purpose. We identify these and remove them from the workspace.

- Infrequently used items: We can move tools or supplies that we rarely need to a storage area. Consequently, this frees up valuable space in the primary work zone.

- Excess inventory: Holding onto too much of something can lead to clutter and wasted space. We identify and address any unnecessary quantities of materials or supplies.

- Personal items: While comfort is important, excessive personal belongings can contribute to clutter. We establish guidelines for what is appropriate to keep in the workspace.

To effectively Sort, we often use a technique called “red tagging.” We attach a red tag to any item that we suspect might be unnecessary.

This tag includes information like the item’s description, the date tagged, and who tagged it. We then move these red-tagged items to a designated “red tag area” for a defined period. If no one needs the item during this time, we dispose of it.

This process ensures that we don’t inadvertently throw away something essential while actively decluttering. We are making conscious decisions about what stays and what goes, based on actual need.

2. Set in Order (Seiton): We Arrange for Efficiency

Once we have sorted out the unnecessary items, the Set in Order phase focuses on organizing the remaining items in a logical and efficient manner. We aim to create a workspace where everything has a designated place, and it’s easy for anyone to find and retrieve what they need. This involves:

- Assigning locations: We determine the best place for each necessary item based on factors like frequency of use, workflow, and safety. Items used most often should be readily accessible.

- Visual cues: We use visual aids like labels, color-coding, and outlines (shadow boards) to clearly indicate where items belong. This makes it immediately obvious if something is missing or in the wrong place.

- Ergonomics: We consider the physical well-being of the people using the workspace when arranging items. Frequently used tools should be within easy reach to minimize unnecessary movement and strain.

- Workflow optimization: We arrange tools and materials in a way that supports the natural flow of work, reducing wasted motion and time spent searching.

Think of a well-organized toolbox where each tool has its specific slot. You can instantly see if a tool is missing, and you don’t waste time rummaging through a jumbled mess. During a 5S event, we strive to bring this level of organization to the entire workspace.

We are creating a system where “a place for everything, and everything in its place” becomes a reality, boosting productivity and reducing frustration.

Also Read: What is Total Preventive Maintenance?

3. Shine (Seiso): We Clean and Inspect

The Shine phase goes beyond just tidying up. We actively clean the workspace thoroughly and, while doing so, inspect equipment and the environment for any potential problems. This involves:

- Deep cleaning: We clean all surfaces, equipment, and tools, removing dirt, dust, and debris. This creates a more pleasant and safer working environment.

- Preventative maintenance: As we clean, we look for signs of wear and tear, leaks, or other issues that could lead to equipment failure or safety hazards. We address these minor problems proactively.

- Establishing cleaning schedules: First, we determine the cleaning frequency for different areas and equipment. Then, we assign responsibilities to ensure ongoing cleanliness.

- Providing cleaning tools: We make sure that the necessary cleaning supplies and equipment are readily available and in good working order.

Imagine a machine that is regularly cleaned and inspected. We are more likely to spot a loose bolt or a small leak before it becomes a major problem.

The Shine phase of a 5S event instills a culture of cleanliness and proactive maintenance. We are not just cleaning for appearances; we are cleaning to improve safety, extend the life of equipment, and create a more conducive work environment.

4. Standardize (Seiketsu): We Create Consistency

The Standardize phase maintains the improvements made during the first three ‘S’ phases. Therefore, it is crucial to ensure these improvements last over time. We establish clear guidelines and procedures for sorting, setting in order, and shining. This involves:

- Developing best practices: We document the most effective methods for organizing and cleaning the workspace. This ensures that everyone follows the same procedures.

- Creating visual standards: We clearly communicate the desired workspace appearance and maintenance. To do this, we use visual aids such as checklists, photographs of the ideal state, and standard layouts.

- Implementing schedules and responsibilities: We assign specific tasks and frequencies for maintaining the 5S standards to individual team members or groups.

- Regular audits: We establish a system to periodically check if employees follow the 5S standards. This system helps us identify any areas that need attention.

Think of a recipe. By standardizing the ingredients and steps, we ensure a consistent and predictable outcome every time. Similarly, in a 5S event, we standardize the processes for maintaining an organized and clean workspace.

We are creating a system that makes it easy for everyone to understand and adhere to the established standards, preventing a slide back into the previous state of disorganization.

Also Read: What Is The 5S Concept in Lean Six Sigma?

5. Sustain (Shitsuke): We Make it a Habit

The final and arguably most challenging phase is Sustain. This is where we focus on making the 5S practices a habit and integrating them into the daily routine of everyone in the workspace. Our goal is to create a culture of continuous improvement and self-discipline. This involves:

- Ongoing training and communication: We ensure all team members understand the importance of 5S. To achieve this, we train them on the established standards and procedures.

- Leadership involvement: Leaders play a crucial role in reinforcing 5S by actively participating in audits, providing feedback, and recognizing those who consistently follow the standards.

- Performance measurement: We may track metrics related to 5S, such as audit scores or the time taken to find tools, to monitor progress and identify areas for further improvement.

- Recognition and rewards: We acknowledge and celebrate individuals and teams that demonstrate strong commitment to 5S, fostering a sense of ownership and pride.

- Continuous improvement (Kaizen): We view 5S not as a one-time event but as an ongoing journey. We encourage everyone to look for opportunities to further refine and improve the 5S practices.

Imagine brushing your teeth every day. It started as a learned behavior but eventually became an ingrained habit. The Sustain phase of a 5S event aims to make the 5S practices just as automatic. We are building a culture where everyone takes responsibility for maintaining a clean, organized, and efficient workspace as a natural part of their daily work.

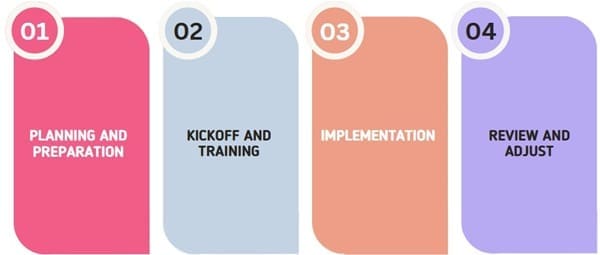

Steps to Conduct a 5S Event

A 5S event is typically a team-based activity that lasts anywhere from a few hours to a few days. The goal is to transform a specific area of the workplace by applying the 5S methodology.

1. Planning and Preparation

Before the event, a detailed plan should be created. This involves selecting the area to be improved, setting objectives, and identifying team members. The team should include people who are familiar with the processes and equipment in that area, as they will have valuable insights into what is necessary and what is redundant.

2. Kickoff and Training

Once the team is assembled, the next step is to provide training on the 5S methodology. It’s essential that all team members understand the purpose of each step and how it contributes to the overall goal of improving efficiency and safety. A kickoff meeting helps to align everyone’s understanding and expectations.

3. Implementation

During the event, the team works together to implement each of the five steps. This might involve sorting through equipment and tools, organizing the workspace, cleaning areas of potential risk, and establishing standardized processes. The event can be fast-paced, and it’s important to keep the momentum going.

4. Review and Adjust

After the event, the team should conduct a review to assess the effectiveness of the changes. We need to evaluate if the objectives were met. We’ll identify successes and areas for improvement. Consequently, we’ll make any necessary adjustments to the procedures, layout, or practices.

Also Read: Importance of 5S in Lean Six Sigma

Why Conduct a 5S Event?

Conducting a 5S event brings a multitude of benefits to an organization, impacting various aspects of its operations:

- Increased Efficiency and Productivity: When everything has its place and is easy to find, we significantly reduce the time wasted searching for tools, materials, or information.

- Improved Safety: A clean and organized workspace is inherently safer. We eliminate tripping hazards, reduce the risk of accidents caused by misplaced items, and ensure that safety equipment is readily accessible.

- Enhanced Quality: By keeping equipment clean and in good working order through the Shine phase, we can reduce the likelihood of defects and ensure consistent product or service quality.

- Reduced Costs: 5S can lead to cost savings by reducing waste (of materials, time, and space), minimizing equipment downtime due to better maintenance, and optimizing inventory levels.

- Better Space Utilization: By removing unnecessary items and organizing the remaining ones efficiently, we can free up valuable workspace, potentially avoiding the need for costly expansions.

- Improved Employee Morale and Engagement: Working in a clean, organized, and safe environment can significantly improve employee morale and job satisfaction. When people feel that their workplace is well-maintained, they tend to take more pride in their work.

- Enhanced Visual Management: 5S creates a visually clear and understandable workplace. Anyone can quickly see if something is out of place or if standards are not being met, facilitating better communication and problem-solving.

- Foundation for Continuous Improvement: 5S is often considered a foundational element of Lean manufacturing and other continuous improvement methodologies.

- Improved First Impressions: A well-organized workspace creates a positive impression on visitors, customers, and stakeholders, showcasing the organization’s commitment to efficiency and quality.

- Empowered Workforce: By actively involving employees in the 5S event and giving them ownership of their workspace, we foster a sense of responsibility and empower them to contribute to a better work environment

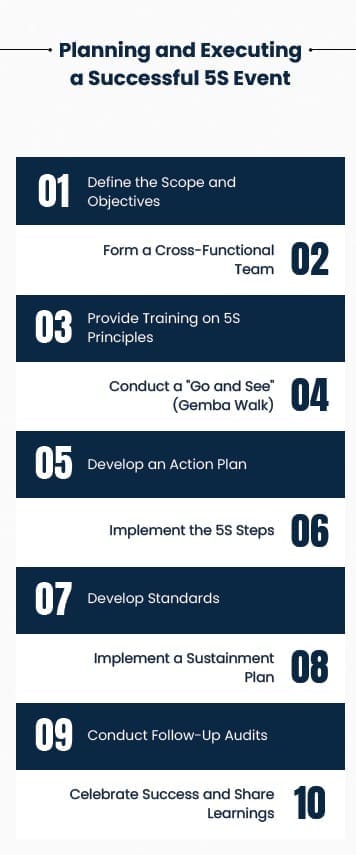

Planning and Executing a Successful 5S Event

To maximize the benefits of a 5S event, careful planning and effective execution are essential. Here are some key steps we take:

- Define the Scope and Objectives: We clearly identify the specific area or process that the 5S event will target and define the desired outcomes. What problems are we trying to solve? What improvements do we hope to achieve?

- Form a Cross-Functional Team: We assemble a team of individuals who work in the targeted area or are directly involved in the process. This ensures diverse perspectives and fosters ownership.

- Provide Training on 5S Principles: We ensure that all team members understand the 5S methodology and their roles in the event.

- Conduct a “Go and See” (Gemba Walk): We observe the current state of the target area to identify areas of waste, disorganization, and potential safety hazards. We take photos to document the “before” condition.

- Develop an Action Plan: Based on the observations, we create a detailed plan outlining the activities for each of the 5S phases, assigning responsibilities and setting timelines.

- Implement the 5S Steps: The team works collaboratively to Sort, Set in Order, and Shine the designated area, following the action plan.

- Develop Standards: The team creates visual standards and procedures for maintaining the improved state.

- Implement a Sustainment Plan: We establish a system for ongoing audits, training, and reinforcement to ensure that the 5S practices become ingrained.

- Conduct Follow-Up Audits: We regularly check whether the 5S standards are being followed and provide feedback and coaching as needed.

- Celebrate Success and Share Learnings: We recognize the team’s efforts and share the results of the 5S event with the wider organization to promote adoption and learning.

Benefits of a 5S Event

Implementing a 5S event brings numerous benefits to an organization, ranging from improved efficiency to enhanced safety. Below are some of the most notable advantages:

- Improved Productivity – By organizing the workplace and reducing time spent searching for tools, employees can focus more on their tasks, leading to a significant increase in productivity.

- Reduced Waste – The 5S event helps eliminate unnecessary items, which not only frees up space but also reduces waste. Streamlining processes eliminates inefficiencies and ensures that resources are used effectively.

- Enhanced Safety – By maintaining cleanliness and order in the workplace, potential hazards such as trip hazards, fire risks, or faulty equipment are identified and resolved quickly.

- Employee Morale – A clean, organized, and well-maintained workspace promotes a positive work environment, which can improve employee morale and engagement.

- Cost Savings – By minimizing waste, reducing downtime due to maintenance, and improving efficiency, businesses can realize significant cost savings over time.

Challenges and Pitfalls of 5S Events

While 5S events bring numerous benefits, they are not without challenges. Here are some common obstacles organizations face when implementing 5S:

- Resistance to Change – Employees may be reluctant to change established routines or may not see the value in implementing 5S. Effective communication and leadership are crucial to overcoming resistance.

- Sustainability Issues – Once the initial 5S event is over, it can be difficult to sustain the improvements. Without regular audits, check-ins, or reinforcements, it’s easy to slip back into old habits.

- Lack of Engagement – For a 5S event to be successful, it must be a team effort. If employees are not actively involved in the process, they may not fully embrace the changes.

Final Words

A 5S event is more than just a cleanup activity. Instead, it is a structured and collaborative approach to creating a better workplace. We actively engage in the five ‘S’ phases: Sort, Set in Order, Shine, Standardize, and Sustain. Through this involvement, we achieve significant improvements in efficiency, safety, quality, and employee morale.

Planning and commitment are crucial for a successful 5S event. Nevertheless, the tangible benefits of a well-executed event make it a valuable tool for any organization striving for continuous improvement and operational excellence. We embrace the power of 5S to transform our workspaces. This allows us to cultivate a culture of order, efficiency, and pride in our work.

About Six Sigma Development Solutions, Inc.

Six Sigma Development Solutions, Inc. offers onsite, public, and virtual Lean Six Sigma certification training. We are an Accredited Training Organization by the IASSC (International Association of Six Sigma Certification). We offer Lean Six Sigma Green Belt, Black Belt, and Yellow Belt, as well as LEAN certifications.

Book a Call and Let us know how we can help meet your training needs.

Described in easy way

The “sustain” section is lacking in definition and instruction compared to the others, which is challenging because it’s the hardest of all the “S”s to perform correctly.

Hanna,

Good mmorning. Thank you for your comments. We will revisit the “Sustain” section and add more detail to instruct you on how to sustain 5S Improvements.