Quality improvement teams consist of cross-functional groups of professionals who work collaboratively to identify, analyze, and solve quality-related problems within organizations. These teams are often ad hoc collections of various professions and/or occupations, working together in time-limited ways to accomplish specific improvement objectives.

Unlike traditional work groups, quality improvement teams focus specifically on enhancing processes, reducing defects, and implementing sustainable solutions. They bring together diverse perspectives, expertise, and experiences to tackle complex challenges that require multidisciplinary approaches.

These teams operate using structured methodologies and data-driven approaches to ensure their efforts produce measurable results. They typically follow established frameworks like DMAIC (Define, Measure, Analyze, Improve, Control) or Plan-Do-Study-Act (PDSA) cycles to guide their improvement activities.

Table of contents

- What are Quality Improvement Teams?

- Key Components of Quality Improvement Teams

- How to Build and Manage Quality Improvement Teams?

- Essentials for Effective Quality Improvement Teams

- Best Practices for Quality Improvement Teams

- Quality Improvement Teams in Different Industries

- Tools for Effective Quality Team Collaboration

- Common Challenges and Solutions

- Measuring Quality Improvement Team Success

- Advanced Quality Improvement Strategies

- Final Words

- Frequently Asked Questions (FAQs) on Quality Improvement Teams

- Related Articles

What are Quality Improvement Teams?

Quality improvement teams (QITs) are groups of individuals tasked with analyzing processes, identifying inefficiencies, and implementing solutions to enhance quality. These teams typically include members from various departments, bringing diverse perspectives to tackle challenges. By leveraging quality improvement strategies, QITs aim to reduce errors, improve efficiency, and elevate customer satisfaction.

For example, in healthcare, a QIT might focus on reducing patient wait times, while in manufacturing, they could streamline production processes. The core of their work lies in continuous quality improvement (CQI), ensuring ongoing progress toward excellence.

Public, Onsite, Virtual, and Online Six Sigma Certification Training!

- We are accredited by the IASSC.

- Live Public Training at 52 Sites.

- Live Virtual Training.

- Onsite Training (at your organization).

- Interactive Online (self-paced) training,

The Evolution of Quality Improvement Teams

Quality improvement teams emerged from the Total Quality Management (TQM) movement and have evolved significantly over the decades. Initially popularized in manufacturing through approaches like Six Sigma and Lean methodologies, these teams have successfully expanded into healthcare, education, and service sectors.

A Healthcare Quality Improvement (QI) program is a set of focused activities designed to monitor, analyze, and improve the quality of processes to improve the healthcare outcomes in an organization. By gathering and analyzing data in key areas, a hospital can effectively implement change.

The modern approach to quality improvement teams incorporates best practices from various disciplines, including project management, change management, and organizational psychology. This evolution has resulted in more effective team structures and improved outcomes across industries.

Why Are Quality Improvement Teams Important?

QITs play a critical role because they:

- Enhance Efficiency: Streamline processes to save time and resources.

- Boost Quality: Improve products or services to meet customer expectations.

- Foster Collaboration: Encourage cross-departmental team collaboration for innovative solutions.

- Drive Accountability: Assign clear quality team roles to ensure progress.

By implementing quality management techniques, QITs create measurable, sustainable improvements.

Key Components of Quality Improvement Teams

To succeed, QITs rely on several core elements:

1. Clear Quality Team Roles and Responsibilities

Defining quality improvement team roles ensures everyone contributes effectively. Common roles include:

- Team Leader: Guides the team, sets goals, and oversees progress.

- Data Analyst: Collects and analyzes data to identify improvement areas.

- Process Expert: Provides insights into specific workflows or systems.

- Facilitator: Coordinates meetings and ensures open communication.

A quality team roles and responsibilities template helps document these duties clearly. For instance:

| Role | Responsibilities |

| Team Leader | Set objectives, monitor progress |

| Data Analyst | Analyze metrics, identify trends |

| Process Expert | Suggest process improvements |

2. Structured Quality Improvement Process

QITs follow frameworks like Plan-Do-Study-Act (PDSA) or Six Sigma to guide their efforts:

- Plan: Identify issues and develop solutions.

- Do: Implement changes on a small scale.

- Study: Analyze results using quality metrics.

- Act: Scale successful changes or adjust strategies.

These frameworks ensure systematic continuous improvement.

3. Effective Collaboration Tools

Quality team collaboration relies on tools like:

- Trello or Asana: Track tasks and progress.

- Microsoft Teams: Facilitate communication and file sharing.

- Minitab or Tableau: Analyze quality improvement data.

These tools enhance teamwork in quality management by keeping everyone aligned.

Also Read: What is Advanced Product Quality Planning?

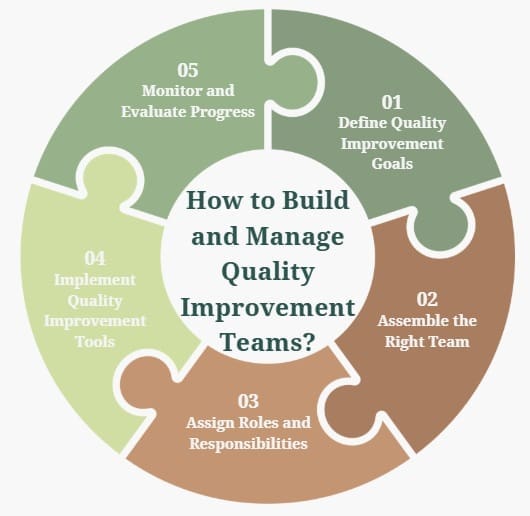

How to Build and Manage Quality Improvement Teams?

Creating a high-performing QIT involves careful planning. Here’s a step-by-step guide:

Step 1: Define Quality Improvement Goals

Set specific, measurable objectives. For example, a healthcare QIT might aim to reduce medication errors by 20% within six months. Clear goals align the team and guide quality improvement strategies.

Step 2: Assemble the Right Team

Select members with diverse skills. For instance, a manufacturing QIT might include engineers, quality inspectors, and production staff. Ensure roles in a quality team cover all necessary expertise.

Step 3: Assign Roles and Responsibilities

Use a quality improvement roles and responsibilities template to assign tasks. For example:

- Team Leader: Develops the improvement plan.

- Data Analyst: Tracks quality metrics like defect rates.

- Facilitator: Ensures meetings stay productive.

Step 4: Implement Quality Improvement Tools

Use tools like:

- Cause-and-Effect Diagrams: Identify root causes of issues.

- Control Charts: Monitor process stability.

- Pareto Charts: Prioritize problems based on impact.

These quality management tools help teams analyze data and make informed decisions.

Step 5: Monitor and Evaluate Progress

Track quality improvement metrics like error rates, cycle times, or customer satisfaction scores. Regular reviews ensure the team stays on track. If goals aren’t met, adjust strategies using continuous quality improvement principles.

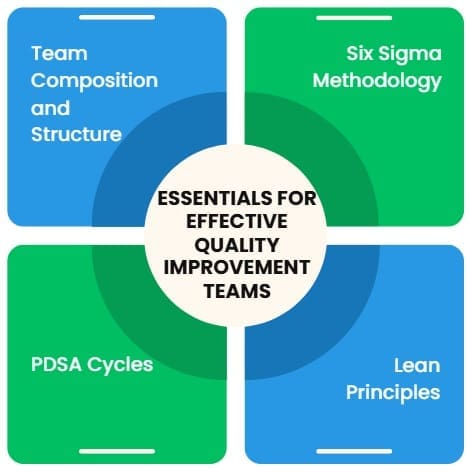

Essentials for Effective Quality Improvement Teams

Team Composition and Structure

Successful quality improvement teams require careful consideration of membership and structure. At least one team member should have experience with improvement methods, such as through participating in past quality improvement (QI) initiatives or through formal QI training.

A team member with improvement methods expertise can provide additional technical support by helping the team determine what to measure, assisting in design of simple, effective measurement tools, and providing guidance on collection, interpretation, and display of data.

Essential team roles include:

- Team Leader: Provides direction, facilitates meetings, and maintains focus on objectives

- Subject Matter Experts: Bring specialized knowledge relevant to the improvement area

- Process Owners: Understand current workflows and can implement changes

- Data Analysts: Collect, analyze, and interpret improvement metrics

- Frontline Staff: Provide practical insights and ensure solutions are implementable

Methodological Frameworks

Quality improvement teams utilize various structured approaches to guide their work:

Six Sigma Methodology

The use of teams that are assigned well-defined projects that directly affect the organization’s bottom line. Training in statistical thinking at all levels. Emphasis on the define, measure, analyze, improve, and control (DMAIC) approach to problem solving. This methodology focuses on reducing process variation and eliminating defects through statistical analysis.

Lean Principles

Lean Six Sigma is a team-focused managerial approach that seeks to eliminate resource waste and defects to improve performance. It also strives to optimize time, effort, and talent while assuring production quality and organizational processes. Lean methodologies emphasize waste elimination and value stream optimization.

PDSA Cycles

The Plan-Do-Study-Act approach provides a simple yet effective framework for testing and implementing improvements on a smaller scale before full deployment.

Best Practices for Quality Improvement Teams

To maximize impact, follow these quality improvement best practices:

- Set SMART Goals: Ensure goals are Specific, Measurable, Achievable, Relevant, and Time-bound.

- Encourage Open Communication: Foster a culture where team members share ideas freely.

- Leverage Data: Use quality improvement data to drive decisions.

- Train Team Members: Provide training on quality management techniques like Six Sigma or Lean.

- Celebrate Success: Recognize milestones to boost team morale.

For more tips, explore our Guide to Continuous Quality Improvement.

Quality Improvement Teams in Different Industries

QITs adapt to industry-specific needs:

- Healthcare: Focus on patient safety, reducing wait times, or improving care delivery. For example, a QIT might use PDSA cycles to streamline hospital admissions.

- Manufacturing: Target defect reduction or production efficiency using Six Sigma tools.

- Service Industry: Enhance customer satisfaction by improving service processes.

Each industry requires tailored quality team strategies to address unique challenges.

Tools for Effective Quality Team Collaboration

Technology enhances quality team collaboration. Popular tools include:

- Microsoft Teams: Supports teamwork in quality management with chat and video features.

- Asana: Tracks tasks and deadlines for quality improvement projects.

- Minitab: Analyzes quality metrics for data-driven decisions.

- Tableau: Visualizes quality improvement data for easy interpretation.

These tools streamline quality management collaboration and improve efficiency.

Also Read: 7 Basic Quality Control Tools

Common Challenges and Solutions

QITs face several challenges:

- Resistance to Change: Employees may resist new processes. Overcome this with clear communication and training.

- Lack of Data: Incomplete data can hinder analysis. Use quality management tools to collect reliable metrics.

- Team Conflicts: Differing opinions can stall progress. A facilitator can mediate and keep discussions productive.

- Resource Constraints: Limited budgets or time can strain teams. Prioritize high-impact improvements.

Measuring Quality Improvement Team Success

Evaluate QIT performance using:

- Key Performance Indicators (KPIs): Track metrics like defect rates, cycle times, or customer satisfaction.

- Feedback Surveys: Gather input from team members and stakeholders.

- Post-Project Reviews: Analyze outcomes to identify continuous improvement opportunities.

These metrics ensure quality improvement teams deliver measurable results.

Advanced Quality Improvement Strategies

Once your QIT is established, explore advanced approaches:

- Lean Methodology: Eliminate waste to improve efficiency.

- Six Sigma: Reduce process variation using statistical tools.

- Root Cause Analysis: Use cause-and-effect diagrams to address underlying issues.

These strategies enhance continuous quality improvement efforts.

Final Words

Quality improvement teams represent a powerful mechanism for driving organizational excellence across industries. By bringing together diverse expertise, utilizing structured methodologies, and focusing on data-driven solutions, these teams can achieve significant improvements in quality, efficiency, and customer satisfaction.

The success of quality improvement teams depends on careful planning, strong leadership support, and a commitment to continuous learning and adaptation. Organizations that invest in building effective quality improvement capabilities will find themselves better positioned to compete in today’s demanding business environment.

Also See: Best Lean Six Sigma Training in Cleveland

Frequently Asked Questions (FAQs) on Quality Improvement Teams

What is the ideal size for a quality improvement team?

Quality improvement teams typically work best with 5-8 members. This size allows for diverse perspectives while maintaining effective communication and decision-making. Larger teams may struggle with coordination, while smaller teams may lack necessary expertise.

How long should a quality improvement project typically take?

Most quality improvement projects last 3-6 months, though complex initiatives may extend to 12 months. The timeline depends on project scope, complexity, and organizational factors. Teams should establish clear milestones and regularly assess progress.

What training do quality improvement team members need?

Team members benefit from training in improvement methodologies (Six Sigma, Lean, PDSA), data analysis techniques, project management, and change management. At least one team member should have formal quality improvement training or certification.

How do you measure the success of a quality improvement team?

Success is measured through both process and outcome metrics. Process metrics include error rates, cycle times, and cost savings. Outcome metrics focus on customer satisfaction, employee engagement, and overall organizational performance improvements.

What are the most common reasons quality improvement teams fail?

Common failure factors include lack of senior leadership support, unclear objectives, insufficient resources, poor team composition, and failure to sustain improvements. Addressing these factors proactively significantly increases success rates.

Can quality improvement teams work remotely?

Yes, quality improvement teams can work effectively remotely using virtual collaboration tools, shared dashboards, and regular video meetings. However, some activities may benefit from in-person interaction, particularly during problem-solving sessions.