Table of contents

What Is The 5S Concept in Lean Six Sigma?

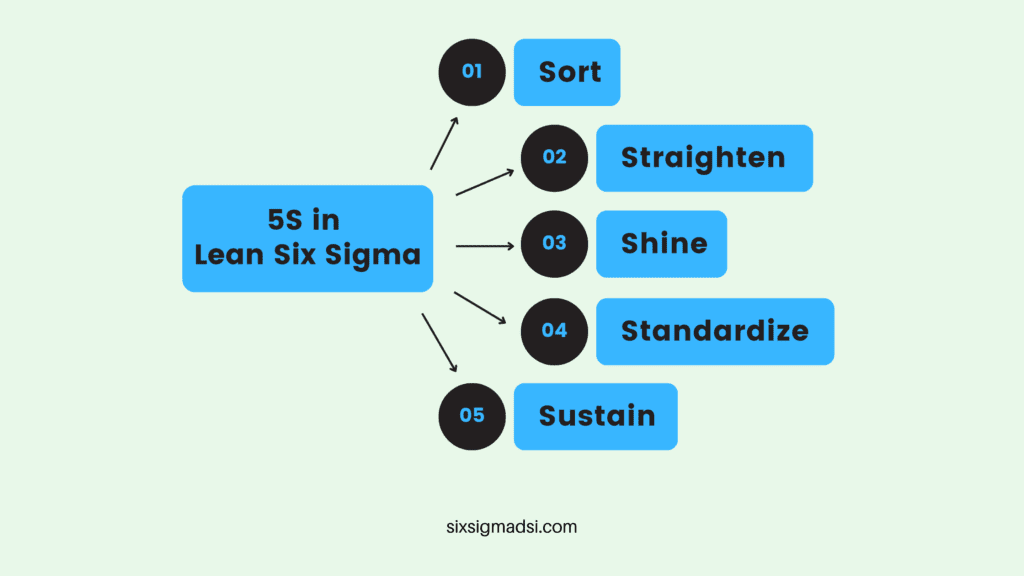

The 5 S steps concept in Lean Six Sigma is an organizational system that aims to optimize productivity and reduce waste by maintaining a clean and orderly work environment and using visual cues for more consistent results. This method is used to “clean up” and organize the workspace in its current configuration. It’s usually the first lean technique that organizations implement.

The 5S pillars of Sort (Seiri), Put in Order (Seiton), Shine (Seiso), Standardize (Seiketsu), and Sustain (Shitsuke) provide a method for organizing, cleaning, and developing a productive workplace. Routines that promote order and organization are vital to the smooth flow of daily activities in a business. This lean approach encourages employees to improve their work conditions, while also teaching them how to reduce waste, downtime unplanned, and in-process inventories.

What Are The Origins of LEAN 5S?

The 5S method has its origins in post-war Japan when leaders of Toyota Industries tried to improve efficiency and reduce manufacturing waste. Toyota Production System is their solution. The Toyota Production System initially was kept secret but foreign companies were well aware of it. The foreign companies were intrigued by how Toyota, Japan’s most prestigious manufacturer, was able to produce so many high-quality products in such a short time. Hiroyuki Hirano was an executive of ULVAC Inc. who created the five pillars. They would later evolve into what we now know as the 5S method.

What is the Purpose of LEAN 5S?

The 5S system aims to increase workplace productivity and ease of work. Space is made to make sense. The materials and tools should be placed in the most logical locations based on how often they are used, who needs them, and where. Cleaning is necessary on a regular basis. Cleaning and organizing have become habits. When the 5S concept is applied correctly in Lean Six Sigma, it can make processes more efficient and safer.

LEAN 5 Benefits

Reduced waste and increased efficiency

The 5S steps system in six sigma encourages businesses to improve their efficiency and reduce waste. The bottom line of a business will be improved. It can be done by improving services and products and reducing costs.

Optimized Organization

These five pillars will reduce the amount of time you spend searching for items, learning how to use them, and returning them. Store parts, tools, and information in a manner that makes them easy to find and use.

Safety Increased

“Waste”, which is to be eliminated, is defined in a broad sense. It includes everything from excess inventory and unsafe conditions to a box of materials left on a busy street that could cause a worker to trip and become injured.

Larger Storage Density

The standard 5S implementation reduces the square footage needed for existing operations. This system allows for greater space utilization by eliminating unnecessary items in production plants.

Morale at work can be improved

It is the main goal of this system to ensure that employees follow procedures as a matter of course and maintain discipline in order to avoid backsliding. This will help employees avoid dark, disorganized workplaces which can lower morale.

How to Apply the 5S Pillars?

The 5S method is a cycle: sort, order, shine and standardize. This leads to continuous improvement.

Sort

Sort, the first S out of the 5 in six sigma, is a method of eliminating items that are unnecessary for the current production process. Red tagging is a visual way to identify unneeded items. It involves evaluating each item and deciding how it should be handled. All items not essential for operation or not located in the correct quantity or location are marked with a red tag. After the red-tagged items have been identified, they are moved to a central storage area where they can be disposed of, recycled, or reassigned. Sorting allows organizations to save valuable floor space, eliminate broken tools, scrap, and surplus raw materials, and reclaim valuable storage.

Shine

The next step, after the clutter has been removed and the remaining items have been organized, is to clean the area thoroughly. To maintain this improvement, daily follow-up cleaning will be required. Clean environments allow workers to detect malfunctions such as leaks and vibrations. They can also notice misalignments, breaks, and other problems. If these changes are not addressed, they could cause equipment failures and production losses. Before beginning the Shine pillar, organizations often set Shine targets, assignments, methods, and tools. Set in Order Set In Order is a method of organizing items in a way that makes them easy to use, and labeling them to make them easy to locate and store. Set in Order is only possible after the first pillar Sort has been completed. Set In Order strategies include painting the floor, attaching labels to indicate proper storage methods and locations, outlining areas and locations, installing modular shelving, and installing cabinets.

Standardize

After the first 3 5 S have been implemented in six sigma, standardizing the best practices within the workplace is the next step. Standardization is the method used to maintain the three first pillars. It creates consistency in the way tasks and procedures are performed. This process involves assigning job responsibilities for 5S (Sort in order, Shine), integrating 5S tasks into normal work, and checking the maintenance of 5S. Standardizing 5S procedures can be done with a variety of tools, including job cycle charts (e.g. signs, placards, and display scoreboards), visual cues such as signs, placards, and scoreboards, scheduling “five-minute 5S periods” and checklists. Standardize’s second component is prevention. This includes preventing the accumulation of unwanted items, preventing broken procedures, and preventing materials and equipment from becoming dirty.

Maintain

Maintaining, or making it a habit to maintain correct procedures is the hardest S to achieve out of the 5 in six sigma. It can be hard to change entrenched behavior, and it is common to want to go back to the old way of doing things. Sustain is focused on defining the new standard and status quo of workplace organization. The other pillars won’t last very long without the Sustain Pillar. Signs and posters, newsletters and pocket manuals are all tools that can be used to sustain 5S. Organizations usually try to reinforce the 5S message in different formats until it is “the way that things are done.”

Visual Management and LEAN 5S

Visual control is another name for visual management. Visual signals are used to convey key information. Visuals such as photos, diagrams, and color coding are used. This style of management allows employees to grasp information quickly. You can use visual management techniques to ensure that everyone is aware of the current status of work processes. A green light or an on-light indicates that the process is going smoothly. A red light indicates that there is a fault.

The 5S steps system in six sigma is a visual control that emphasizes organization and can increase productivity. Visual markings can be used by workers to mark storage areas to assist them in returning materials to their correct locations. To organize work cells, floor markings can act as boundaries. Signs can be placed on the floor to indicate where the recycling bins or trash cans are located. These visual tools allow businesses to communicate with employees without having to say anything.

Visual Workplace and LEAN 5S

Visual workplaces are places where people can access information using visual tools. The visual explanation of workplace processes reduces the number of questions employees have to ask. Visual workplaces can be described as “self-explaining, self-ordering and self-regulating” because they rely on visual signals to allow them to function with minimum effort. Visual workplaces are organizations that use 5S to make their organizational systems visible.

Have you applied the 5S pillars to your project?

Tell us about your experience in the comments below!