Table of contents

Lean Event Tollgate Review and Deliverables

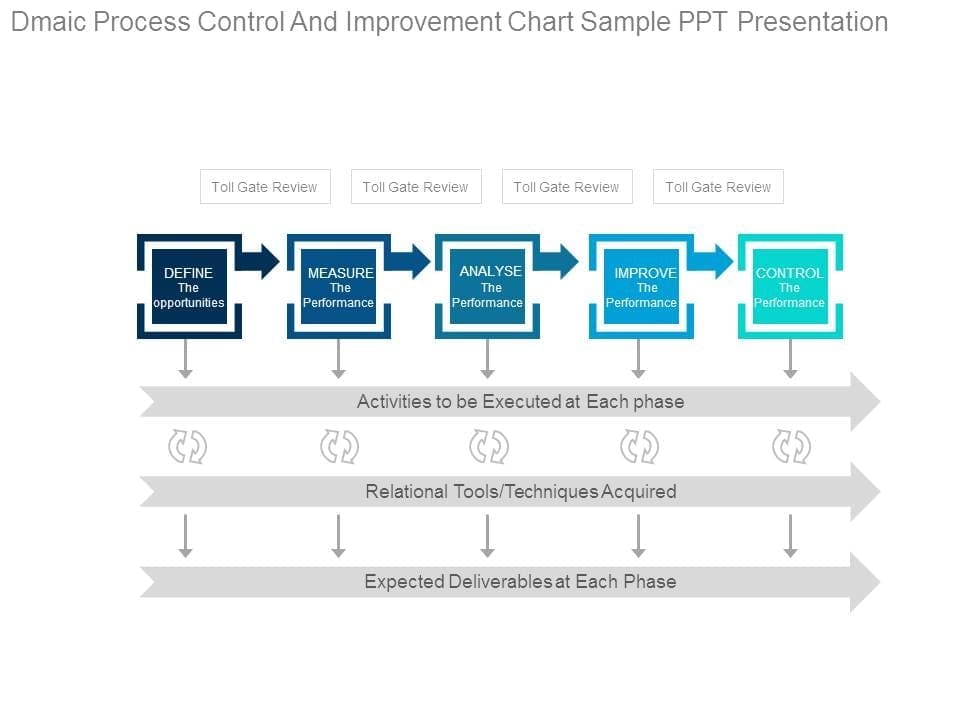

The Lean Event Tollgate Review Meeting’s process will help you determine if the goals in the Lean Event stages (PDCA or DMAIC) have been completed and whether you can move on to the next stage. A Lean Event Tollgate Review Meeting’s process is like a checkpoint at which the various team members meet with a project Champion and determine whether the work has been performed as indicated in the project plan and whether the objectives mentioned have been achieved

PLAN/DEFINE Phase

Lean Event “Day 0” Tollgate Review Project Process and Deliverables Meeting

- This should happen no less than two weeks before the Lean Event (Day 1-5) takes place

- Has the Project Team been developed?

- Is the Team and Project Sponsored by a Champion or Business Leader?

- Does the Team include SME’s?

- Have they had the Lean and Six Sigma White Belt Training?

- Has the Project Charter been developed?

- (The following questions should help determine the answer)

Business Case

- What are the compelling business reasons for embarking on this project?

- Is the project linked to key business goals and objectives?

- What key business process output measure(s) will the project leverage and how?

- What are the rough order estimates on cost savings/opportunities on this project?

Problem Statement (Starting Line):

- What specifically is the problem?

- Where does it occur?

- When does it occur?

- What is its extent?

Goal Statement (Finish Line):

- What is the goal or target for the improvement Team’s project?

- Do the problem and goal statements meet the SMART criteria (Specific, Measurable, Attainable, Relevant, and Time-bound)?

- Has anyone else (internal or external to the organization) attempted to solve this problem or a similar one before? If so, what knowledge can be leveraged from these previous efforts?

- How will the Project Team and the Organization measure complete success for this project?

- What are the physical boundaries of the Scope?

- What is in bounds and what is not?

- How does the Project Manager ensure against Scope Creep?

- Is the Project Scope manageable? What constraints exist that might impact the team?

Milestones:

- When was the project start date?

- When is the estimated completion date?

- Is the project currently on schedule according to the plan?

- Has a project plan with milestones been developed?

- Is there a critical path (due dates to each phase of the DMAIC) to complete the project?

- How will variation in the actual durations of each activity be dealt with to ensure that the expected project completion date is met?

3. Do we understand the Customers’ Requirements?

- Have the customers been identified?

- Has the improvement team collected the ‘Voice of the Customer’ (obtained feedback – qualitative and quantitative)?

- What customer feedback methods were used to solicit their input?

- Have the customer needs been translated into specific, measurable requirements?

4. Has a SIPOC diagram been produced describing the Suppliers, Inputs, Process, Outputs, and Customers?

Lean Event “Day 0” Deliverables:

- Project Team has been developed and is sponsored by a Champion or Business Leader.

- Project Management Charter, including Business Case, Problem and Goal Statements, Project Scope, Milestones, Roles and Responsibilities, and Communication plan.

- Completed SIPOC representation, describing the Suppliers, Inputs, Process, Outputs, and Customers.

- Red flags and recommendations for resolving them defined.

- Next steps documented.

- Approval of “Day 0” signed by Project Champion.

Lean Event “Day 1-5” Tollgate Review Project Meeting Process:

DO/MEASURE/ANALYZE Phase

Lean Training

- Has an introduction to Lean Training been completed?

- Does the Team understand the concepts of Flow, TAKT Time, Pull and Kanban, Waste, NVA/VA, Reduction of Complexity (reduction of steps in a process) and 5S?

Performance Baseline

- What is the current process performance baseline?

- Do you have historical data to support performance baseline?

- Do we have graphical representations of the data through Control Charts or Graphical Summaries?

Characterize the Current State

- Have we developed a Current State VSM?

- Have we displayed the Current Process Elapsed Time?

- Have we visually separated Value Added processes/time from Non Value Added processes/time?

- What is the Current State Elapsed Time?

- What is the Current State VA%?

- If we are in a SMED event, have we separated Internal from External Process/Time?

- Have we developed a Spaghetti Diagram to represent travel distance and time?

Develop the Future State:

- Have we developed a Future State Value Stream Map

- Have we displayed the Future State Process Elapsed Time?

- Have we visually separated Value Added processes/time from Non Value Added processes/time?

- What is the Future State Elapsed Time?

- What is the Future State VA%

- If we are in a SMED event, have we separated Internal from External Process/Time?

- Have we developed a Spaghetti Diagram to represent Future State travel distance and time?

CHECK/ANALYZE/IMPROVE Phase

Risk Manage the Proposed Improvements

- Have we developed a D-FMEA to address potential risks of implementing improvements?

- How were the risks that have been identified addressed?

- Were the improvements to mitigate the risks identified added to the Implementation Plan?

Generating (And Testing) Possible Solutions

- How did the team generate the list of possible solutions?

- What tools were used to tap into the creativity and encourage “outside the box” thinking?

Selecting the Best Solution(s)

- What tools were used to prioritize improvements?

- Are there any constraints (technical, political, cultural, or otherwise) that would inhibit certain solutions?

- Was a pilot designed for the proposed solution(s)?

- Describe the design of the pilot and what tests were conducted, if any?

- What conclusions were drawn from the outcomes of the pilot?

- What lessons, if any, from the pilot were incorporated into the design of the full-scale solution?

ACT/IMPROVE/CONTROL Phase

Designing the “Implementation Plan”

- Has the Team developed an implementation plan?

- Has the Team used a Project Management Tool to manage the improvements (i.e., MS Project or basic Excel Gantt Chart)

- What communications are necessary to support the implementation of the solution?

- How will the Team or the Process Owner(s) monitor the implementation plan to see that it is working as intended?

- What is the Team’s contingency plan for potential problems occurring in implementation?

- How will the organization know that the solution worked?

Lean Event Day 1-5 Tollgate Process Deliverables Meeting:

- Current State of the Process understood through VSM and Spaghetti Map.

- Future State Developed and Risk Managed.

- Implementation plan developed and communicated.

- Small-scale pilot for proposed improvement(s). Pilot data was collected and analyzed.

- Solution for implementation plan established, including schedule/work breakdown structure, resources, risk management plan, cost/budget, and control plan.

- A contingency plan was established.

- Validated improvements.

- Red flags and recommendations for resolving them are defined.

- Approval of report out signed by Project Champion.