Table of contents

- What is Failure Mode Analysis (FMEA)?

- Introduction to Failure Mode (FMEA)

- Understanding Failure Mode Analysis (FMEA)

- Two main types of FMEA

- Why perform Failure Mode and Effects Analysis?

- When to perform Failure Mode and Effects Analysis

- FMEA Relationship to Problem-Solving

- The Steps to Complete an FMEA (Failure Modes and Effects Analysis)

- Related articles

What is Failure Mode Analysis (FMEA)?

FMEA What is it? This article is the third in a four-part series to show you “How to Complete a Six Sigma Root Cause Analysis”. The series covers four tools:

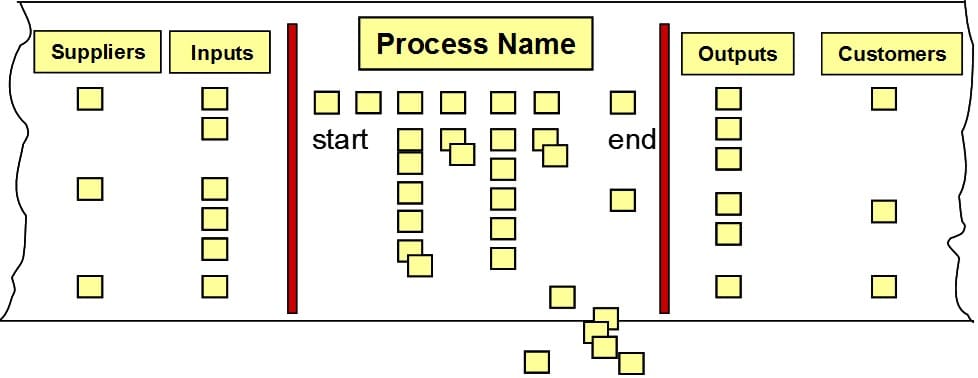

- The SIPOC(R) Diagram

- The Input (or Variables) Map

- The C&E Matrix

- The FMEA (Failure Modes and Effects Analysis)

In this article, we will be discussing FMEA or the Failure Modes and Effects Analysis.

Introduction to Failure Mode (FMEA)

Many high-profile recalls of products are the result of poorly designed products or processes. These product recalls are discussed in public forums. Manufacturers, suppliers, and service providers are shown as being incapable of providing safe products. FMEA (Failure Mode and Effects Analysis) is a method that allows organizations to identify all possible failures during the design phase.

FMEA was developed in the 1950s and is one of the oldest structured reliability improvement techniques. It is still an effective way to lower the chance of failure.

Understanding Failure Mode Analysis (FMEA)

Failure Mode and Effects Analysis (FMEA) is a structured approach that identifies potential failures in the design of a product, process, or product.

Failure modes refer to the possible failures of a process. These failures can cause waste, defects, or other negative outcomes for customers. Failure Mode and Effects Analysis is used to identify, prioritize, and limit these failure modes.

FMEA does not replace good engineering. FMEA enhances engineering rather than replacing it. It uses the expertise and knowledge of a Cross-Functional Team to review the progress of a product/process and assess its risk of failure.

Two main types of FMEA

Process FMEA

Process FMEA (PFMEA), identifies product quality and reliability issues, customer dissatisfaction, safety, or environmental hazards.

- Machines utilized

- Acceptance is affected by measurement systems

- Process performance is affected by the environment

- Human Factors

- Processing methods

- Materials used

Design FMEA

Design FMEA (DFMEA), which examines the potential for product malfunctions, reduced product lives, and safety and regulatory concerns derived:

- Tolerances

- Interfaces with other components or systems

- Engineering Noise: Environments, user profiles, degradation, and systems interactions

- Material Properties

- Geometry

Why perform Failure Mode and Effects Analysis?

The cost of a failure will be lower if it is detected early. The impact of a failure discovered later in product development and launch is more severe.

FMEA is one tool that can be used to detect failure early in product and process design. FMEA is a tool that allows you to identify a product development (PD) failure early.

- Improved Design for Manufacturing and Assembly (DFM/A)

- Solutions at a lower cost

- Standard Work, Legacy, Tribal Knowledge, and Tribal Knowledge

- There are many options for reducing the risk

- Higher capacity for Validation and Verification of Changes

- Design of the product and manufacturing process requires collaboration

This methodology can be used to identify and correct process failures early so you can avoid the negative consequences of mediocre performance.

When to perform Failure Mode and Effects Analysis

It is an innovative idea to conduct a Failure Mode Analysis and Effects Analysis at least once in your life.

- If you set a goal to improve the quality of a particular process,

- You need to learn from and fix the mistakes in a process

- Designing a new product, service, or process

- If you plan to perform an existing process in another way

It is also a clever idea to conduct FMEA periodically throughout the life of a process. For optimal results, quality and reliability must always be checked and improved.

FMEA Relationship to Problem-Solving

FMEA’s Failure Modes are the same as the Problem Statement and Problem Description in Problem Solving. FMEA causes are the same as potential root causes in Problem Solving. FMEA failures are problem symptoms in Problem Solving. This relationship is illustrated by:

- FMEA’s design and process controls are used to verify the root cause of an issue and Permanent Corrective Action (PCA).

- FMEA and Problem Solving can reconcile every failure and cause by cross-documenting failure modes, problem statements, and plausible causes.

- Both the problem statements and descriptions can be linked between the two documents. You can solve problems faster by using easy-to-find, pre-brainstormed information in FMEA.

- For future planning of new products and process quality, data from problem-solving can be added to an FMEA. FMEAs can now be able to identify actual failures and their causes. This makes them more efficient and complete.

- To jump-start Fishbone and Ishikawa diagrams, it is possible to identify potential causes of FMEA. It is not an innovative idea to brainstorm information that is already known.

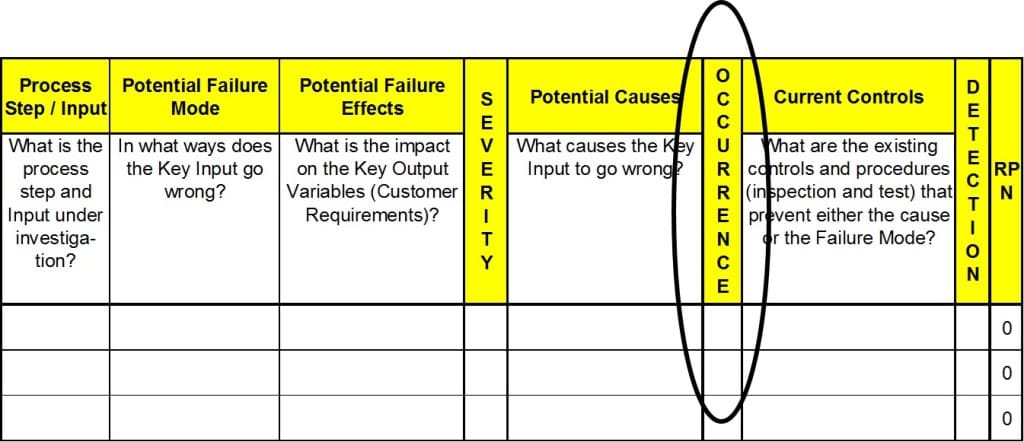

The Steps to Complete an FMEA (Failure Modes and Effects Analysis)

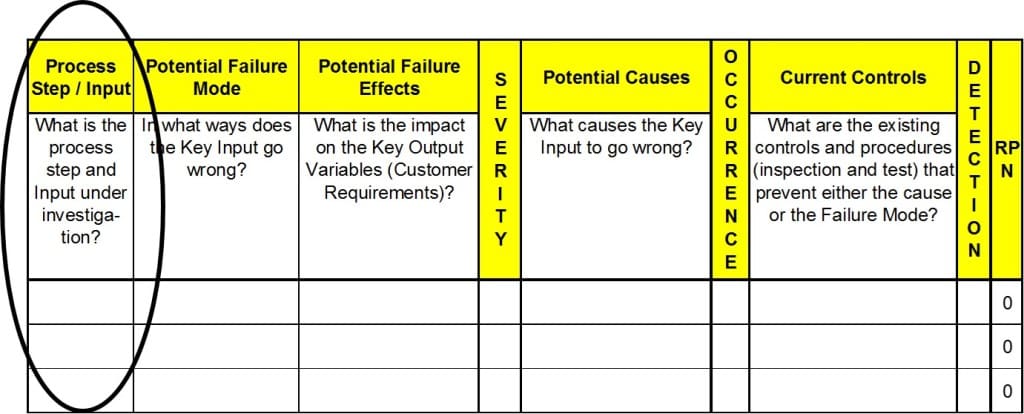

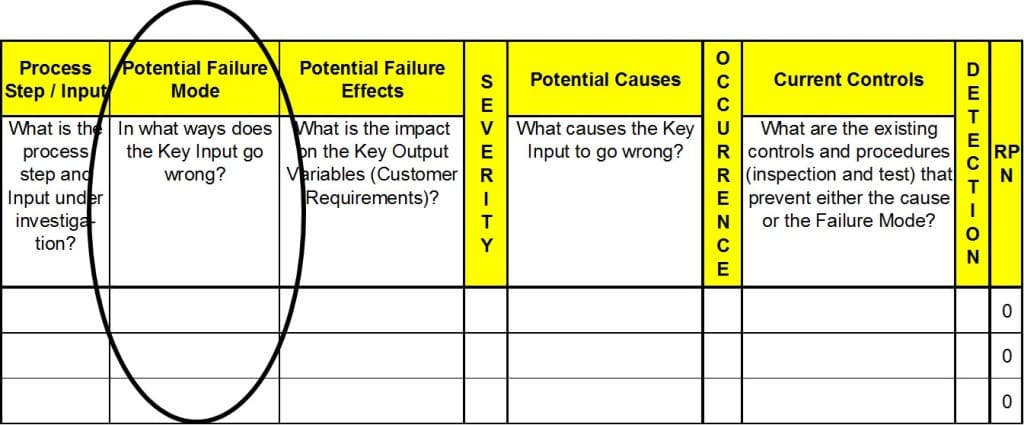

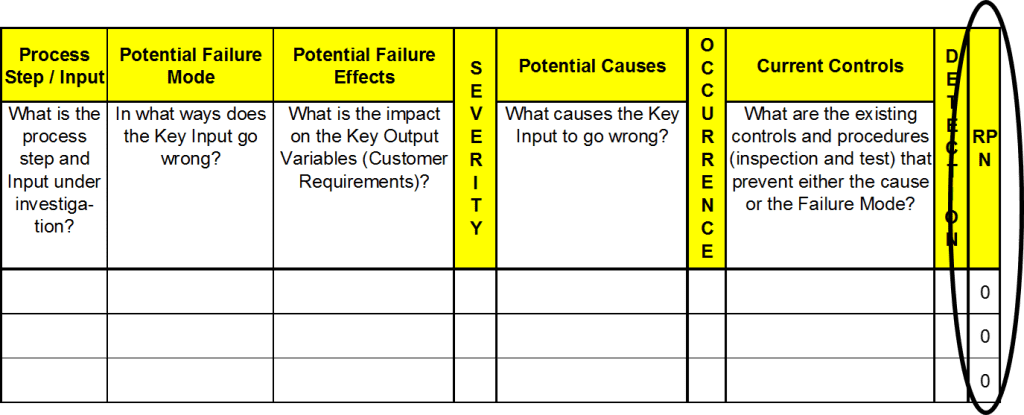

Review and label the Process Steps (using your process map) and the intended function or functions of those steps.

Consider the Potential Failure Modes

Consider the Potential Failure Modes for each component and its corresponding function.

- A potential failure mode represents any way the component or process step could fail to perform its intended function or functions.

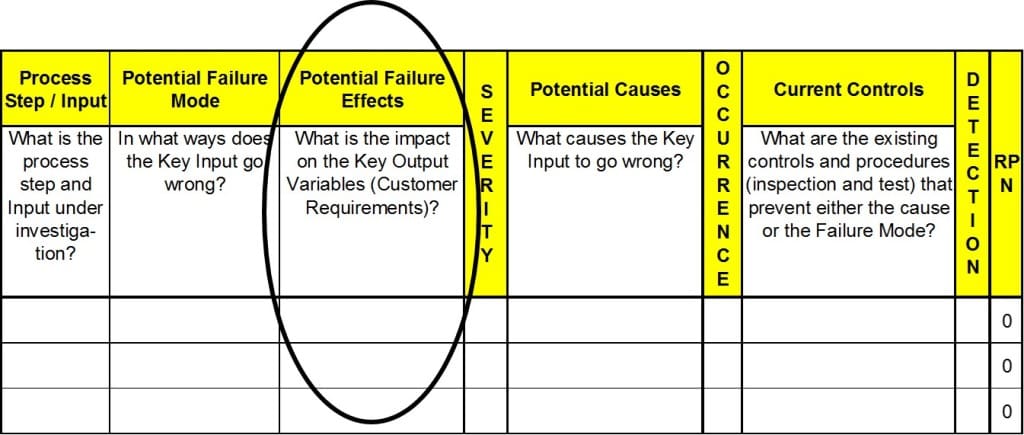

Determine the Potential Failure Effects

Determine the Potential Failure Effects associated with each failure mode. The effect is related directly to the ability of that specific component to perform its intended function.

- The effect should be stated in terms meaningful to product or system performance.

- If the effects are defined in general terms, it will be difficult to identify (and reduce) true potential risks.

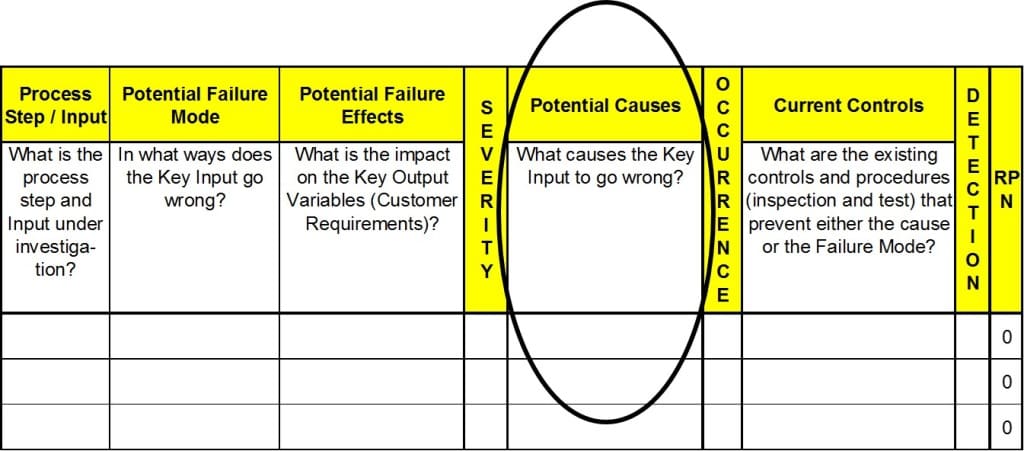

Determine Potential Root Causes

For each failure mode, determine all the Potential Root Causes. Use tools classified as root cause analysis tools, as well as the best knowledge and experience of the team.

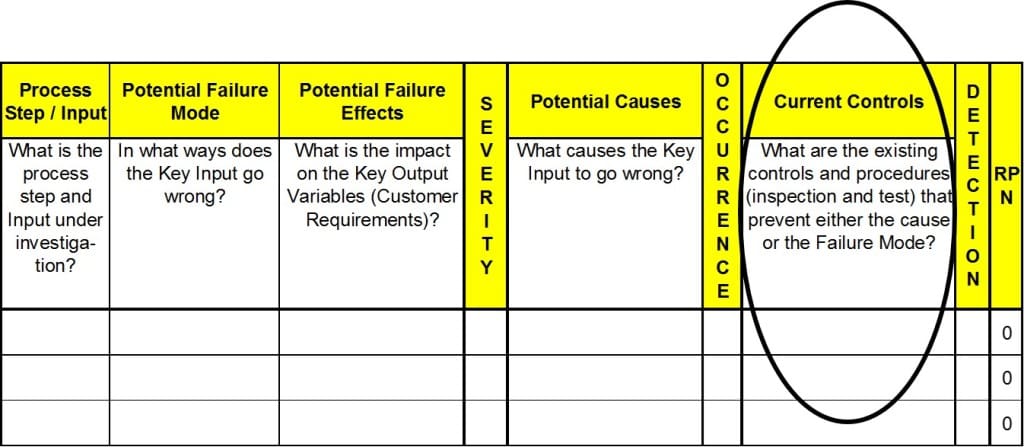

Identify Current Process Controls

For each cause, identify Current Process Controls. These are tests, procedures, or mechanisms that you now have in place to keep failures from reaching the customer.

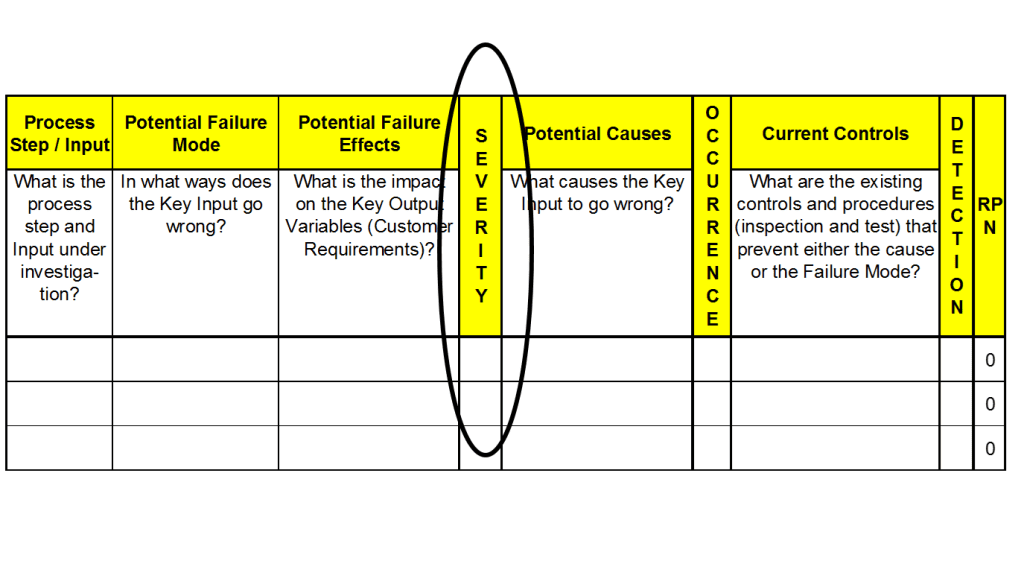

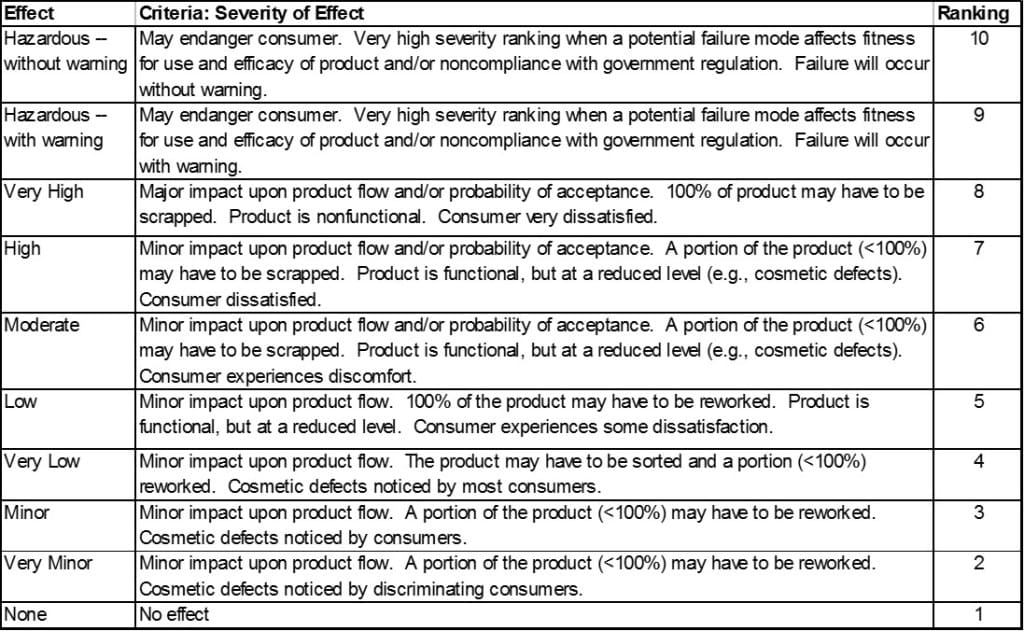

Assign a Severity ranking

Assign a Severity ranking to each effect that has been identified.

- The severity ranking is an estimate of how serious an effect would be should it occur.

- To determine the severity, consider the impact the effect would have on the customer, on downstream operations, or on the employees operating the process.

The severity ranking is based on a relative scale ranging from 1 to 10.

- A “10” means the effect has a dangerously high severity leading to a hazard without warning.

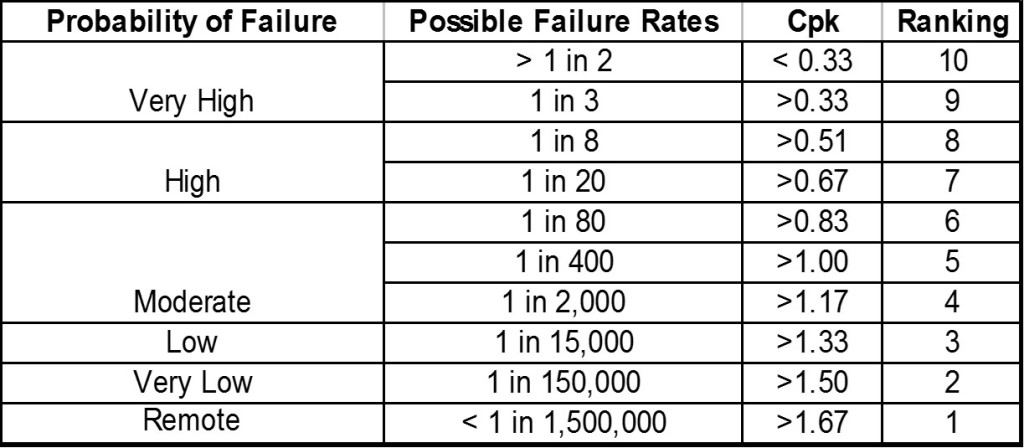

Assign the Occurrence Ranking

- The Occurrence ranking is based on the likelihood, or frequency, that the cause (or mechanism of failure) will occur.

- Once the cause is known, capture data on the frequency of causes. Sources of data may be scrap and rework reports, customer complaints, and equipment maintenance records.

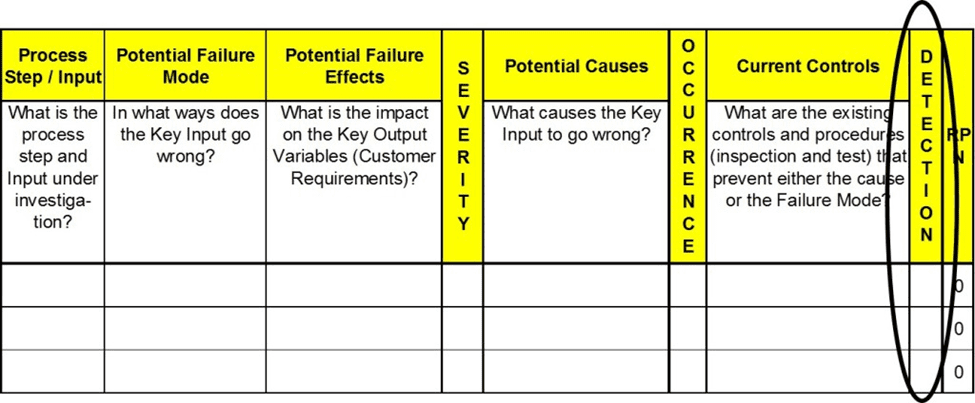

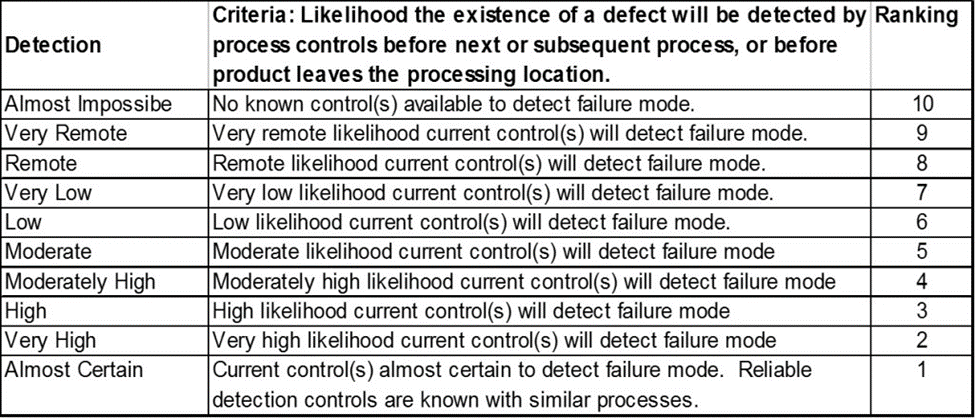

Assign the Detection Rankings

- To assign detection rankings, identify the process or product-related controls in place for each failure mode and then assign a detection ranking to each control. Detection rankings evaluate the current process controls in place.

- A control can relate to the failure mode itself, the cause (or mechanism) of failure, or the effects of a failure mode.

To make evaluating controls even more complex, controls can either prevent a failure mode or cause from occurring or detect a failure mode, cause of failure, or effect of failure after it has occurred.

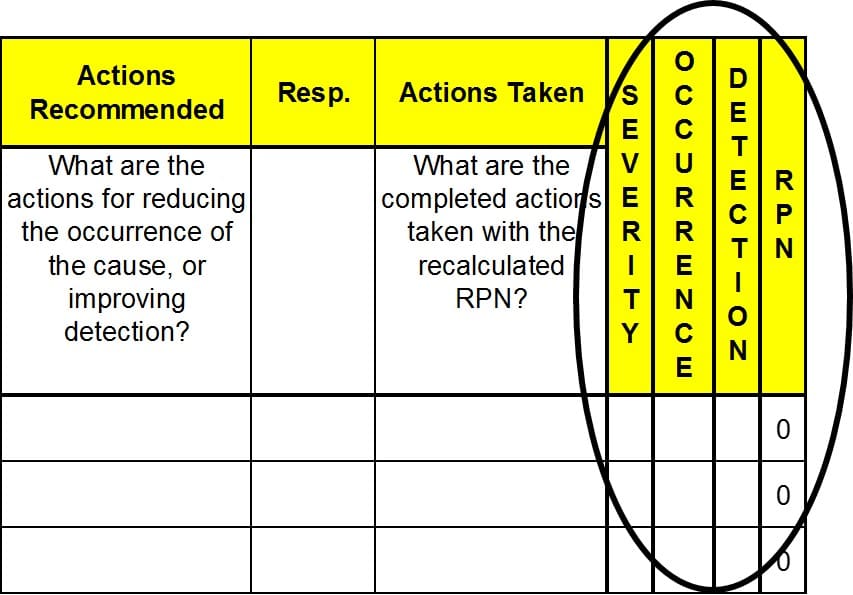

Calculate the Risk Priority Number (RPN)

- The RPN is the Risk Priority Number. The RPN gives us a relative risk ranking. The higher the RPN, the higher the potential risk.

- The RPN is calculated by multiplying the three rankings together. Multiply the Severity ranking times the Occurrence ranking times the Detection ranking

- Calculate the RPN for each failure mode and effect

Prioritize the Risks by Sorting the RPN from Highest Score to Lowest Score. This will help the team determine the most critical inputs and the causes of their failure.

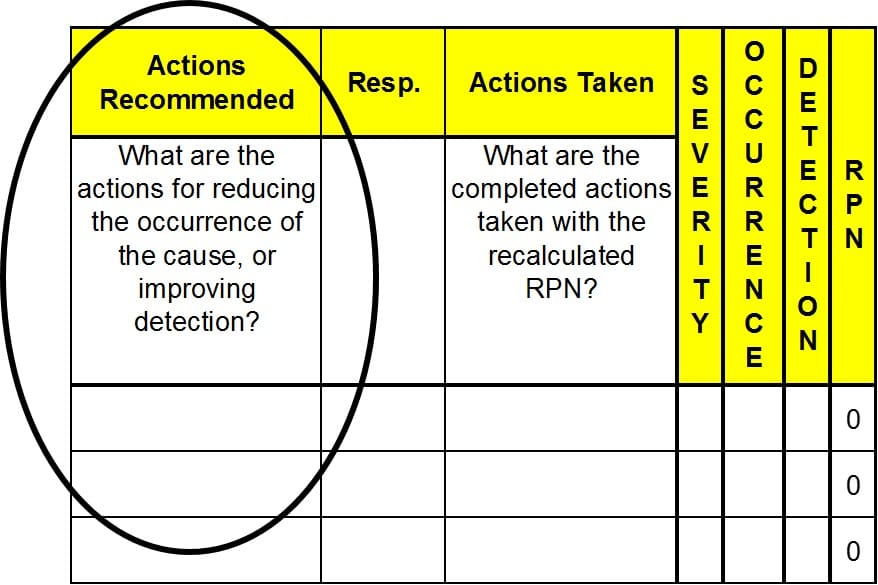

Develop Action Plan

- Acting means reducing the RPN. The RPN can be reduced by lowering any of the three rankings (severity, occurrence, or detection) individually or in combination with one another

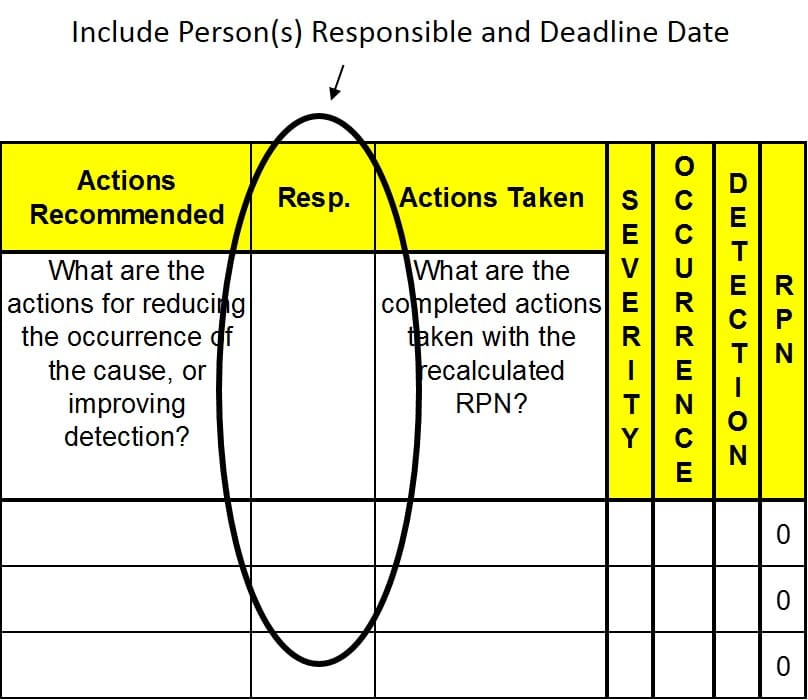

Who is Responsible

- This is an especially crucial step in Acting!

- Be sure to include the person(s) responsible and the deadline

Action Plan

- The Action Plan outlines what steps are needed to implement the solution, who will do them, and when they will be completed.

- Most Action Plans identified during a PFMEA will be of the simple “who, what, & when” category.

- Responsibilities and target completion dates for specific actions to be taken are identified.

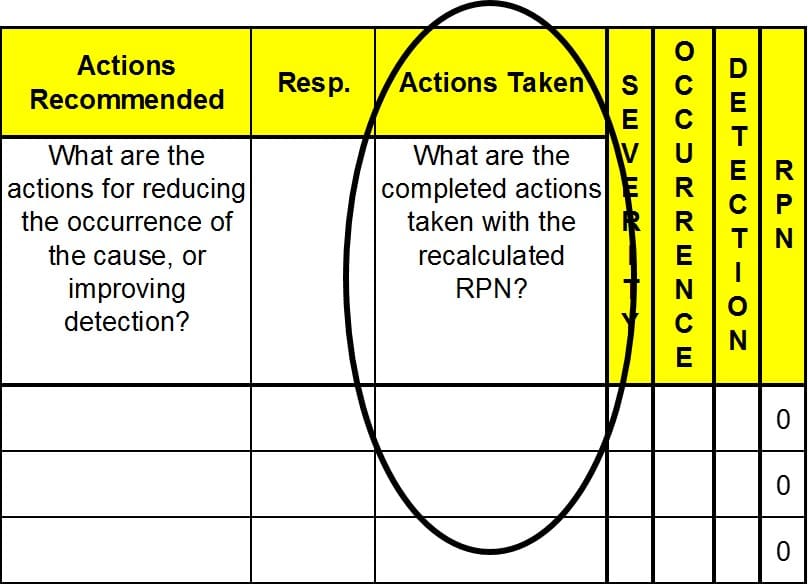

Recalculate the Resulting RPN

- This step in a PFMEA confirms the action plan had the desired results by calculating the resulting RPN.

- To recalculate the RPN, reassess the severity, occurrence, and detection rankings for the failure modes after the action plan has been completed.

I read your information and it’s very useful. The article has help to increase my knowledge on how to analyze and create a pfmea. Thanks for sharing.

I think this is a very good platform to upgrade our knowledge or to be a master in this field. I could prepare a FMEA without any ones help after reading this article.

lot of thanks to Kevin..

To understand the FMEA, it should be to learn by doing. Thank you for Improving our knowledge.

Good quick overview.

very concise step by step procedure and well explained.

thank you so much for sharing.

One question that always comes up, how to quantify the requirements for closure of an FMEA? Or more to the point, what is or are the criteria used for closure?

Mike, great question. In reality, you are never finished. The FMEA matures with the process. When the process changes and experiences new failure modes, then the FMEA is updated. In the short term for the a LSS Project, the FMEA is closed when the Revised RPN’s are below what the company sets as a max RPN.