Table of contents

What is SMED?

SMED process in Lean Six Sigma (Single Minute Exchange of Dies), by definition, is a system that dramatically reduces the time required to complete equipment changeover. Its goal is to convert as many of the changeover steps to “external” (performed as the equipment is still running) and to simplify and streamline all the rest. Single-Minute Exchange of Dies is named after the goal of reducing the time it takes to changeover in other words, less than 10 minutes).

SMED (definition: Single Minute Exchange of Dies) programs have many benefits, including reducing waste and making it more efficient. A successful Six Sigma SMED program will:

- Produce smaller lot sizes. You can change your products more often with faster changeovers

- Lower manufacturing costs. Quicker changeovers mean less equipment downtime.

- Increase machine startup. Standardizing the changeover process ensures consistency in quality.

- Increase flexibility in scheduling, which allows customers to be more responsive to their needs.

The basics of SMED (Single Minute Exchange of Dies)

Shigeo Shingo was a Japanese industrial engineer and inventor of SMED. He was incredibly successful in helping companies reduce changeover times dramatically. His groundbreaking work resulted in a 94% reduction in changeover time (e.g. from 90 minutes down to less than five minutes across a wide variety of companies).

It may seem difficult to believe that changeover times could improve by 20 factors. But consider this simple example:

- Many people find that changing one tire takes 15 minutes.

- A NASCAR pit crew can change four tires in less than 15 seconds.

SMED (definition: Single Minute Exchange of Dies) uses many of the same techniques as NASCAR pit crews. These include performing as many steps as possible before the pit stop starts; using a coordinated group to perform multiple steps simultaneously; creating a standardized and optimized process, and many other steps. The journey from a 15-minute tire swap to a 15-second one can be considered a SMED trip.

SMED (Single Minute Exchange of Dies) is a system that allows for the changeover of elements. There are two types:

- Internal Elements: These are elements that must be completed when the equipment is not in use.

- External Elements: These elements can be added to the equipment while it is still running

SMED is a process that combines as many elements as possible with the goal of streamlining and simplifying all elements.

Implementing SMED

Step 1: Identify a Pilot area

Before you implement Lean SMED (Single Minute Exchange of Dies), the pilot area should be considered. You might choose a process that has the fastest changeover time. This is an important factor. However, it’s not the only thing you should be concerned about.

- Changeover time data shows a wide variation in changeover times. This is evidence of the need for improvement.

- The changeover pilot process is easy to manage and improve but has enough ROI to be attractive

- Employees in the proposed pilot area are engaged and motivated.

- Changeovers happen multiple times a week which helps the team test improvements.

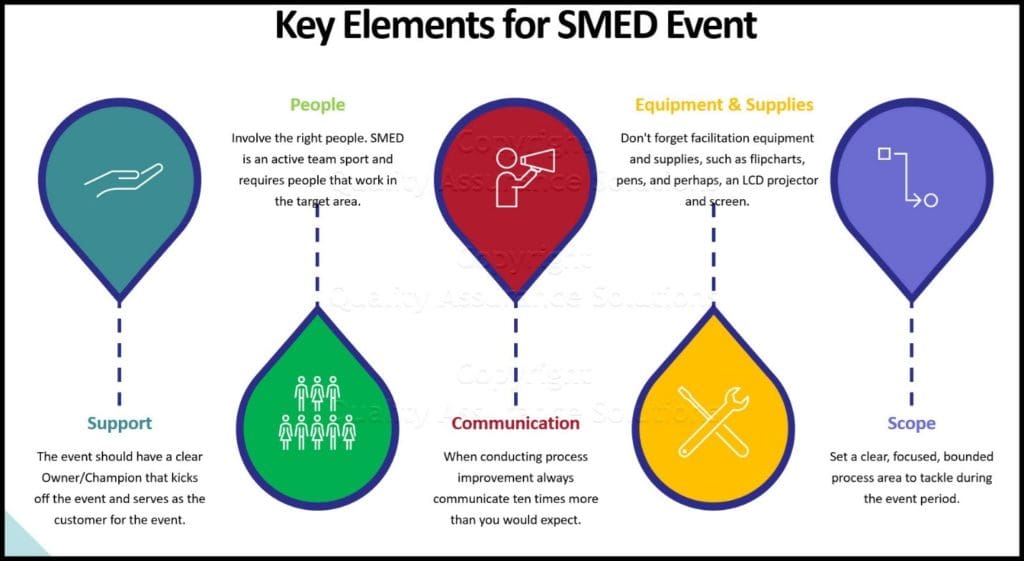

This step is crucial to ensure everyone supports the SMED implementation. This includes all employees involved in the selection process as well as those who will be working on the transition.

Step 2: Identify changeover elements

Once you have identified your pilot area, it is time to collaborate with your Lean Six Sigma SMED (definition: Single Minute Exchange of Dies) team and identify all changeover elements internal and external. Videotaping the entire process of a changeover is a great way to visualize it. Then, sit down with your team and make lists of all elements. You can reorder as necessary. You should include a description of each task and the time it took to complete each task (as well as the cost). You can use this video and outline as a starting point. Here are some things to remember:

- As you videotape a baseline changeover, let multiple members of your team observe the process and make notes. You can compare their notes to what you see while viewing the video. This will ensure that nothing is missed.

- On average, a changeover will result in between 30 and 50 elements.

- Both equipment and human elements can be captured. Many elements can be optimized and are easily manipulated, as we will see.

After completing step 2, you will have a complete list with descriptions and costs for all the changeover elements.

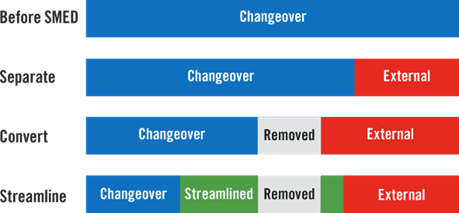

Step 3: Separate External Changeover Elements

Is it possible to perform this element while the machine is running? This is the second question that your team should ask each element that was documented in step 2. Any element that can be completed without any changes while the machine operates must be identified and labeled “external” in the process. In other words, it can be done either before or after the changeover. This step alone can reduce the changeover time by half in many cases.

After completing step 3, you will have an updated list with changeover elements. It can be divided into external elements (before and during the changeover), internal elements, and external elements.

Step 4: Convert Internal Elements into External Elements

What internal elements can be transformed into external elements? This question should be on everyone’s minds as they go through the changeover process. Your team might also ask this question: What would be the best way to make this element extern? And how can it be achieved?

After this evaluation, a list of elements needs to be taken into consideration. This list should be prioritized so that the most promising elements can be dealt with first. Also, do a cost/benefit analysis for each element on the list. The cost of the changes will be measured in terms of labor and materials, while the benefit is determined by how long it takes to complete the transformation.

These are some of the ways to make internal elements external.

- Adjust before the changeover: Use duplicate jigs to perform alignment and other adjustments.

- Preparation in advance: Having parts ready to go in advance can save you a lot of time.

- Modularize equipment. Equipment portability can help reduce interactions and increase the speed of changeover. By designing equipment on wheels, each piece can be highly mobile.

- Equipment modification Make it safer to clean while the machine is in use.

After this step, you will have a new list with changeover elements. This list should contain fewer internal elements. It also includes more external elements. These elements can be performed before or after a switchover.

Step 5: Streamline the remaining changeover elements

What can we do to make this element faster? How can we simplify this element? Your Lean Six Sigma SMED team should then review all elements of your list, to simplify them to make it easier. Prioritize internal elements first before moving on to the external, as the goal is to speed up changeover. To prioritize the steps remaining, use a cost/benefit analysis.

One of the best ways to reduce friction is to replace bolts with quick releases and other functional clamps.

A second way to streamline processes is to have simultaneous operations. Multiple operators can do the same task, just like a NASCAR pit crew changing tires. You should be aware of safety hazards and make sure that work is well-organized and standardized.

After you have completed step 5, update your standard work instructions to facilitate the changeover.

Considerations when Implementing SMED

Lean SMED (definition: Single Minute Exchange of Dies) process can be beneficial for almost every company dealing with changeovers. However, it is important to assess where productivity time is being lost to decide if it should be your priority. This can be done by analyzing hard data such as equipment effectiveness (OEE) and specifically the OEE losses categories that relate to the six major losses. This data can be collected for several weeks to give you a picture of the time being lost. SMED may be an option if you find that the time spent on changeovers is at least 20%. You might also want to consider Total Productive Maintenance processes.

Establish a baseline

You need to decide how you will measure change over time. Changeover time is measured as the difference between the last good part or service of a job at normal speed and the first good part or service of a job at normal speed.

Ask questions

Investigating every internal element and how can potentially be changed to an external element. The following questions can help your SMED team achieve this mentality:

Separate: Can this process be completed while the machine is running?

Convert: How can we convert this internal element into an external one?

Streamline: How can this step in the process be simplified?

Establish best practices

There is a risk that operators may rush through the Lean Six Sigma SMED implementation, which could lead to safety and quality issues. For safety and quality continuity, the best SMED programs use single-point lessons to standardize procedures and processes. You should treat instructions as living documents and have a process to update them as necessary.

Concentrate on human improvement

You should consider two types of improvement when implementing a SMED (definition: Single Minute Exchange of Dies) program: one, a human category that is achieved through organization, preparation, and another, a technical category that is achieved through engineering, optimization, and maintenance. As human improvements are made at setup rather than during implementation, it is easier to ensure that the human factor is in good condition.

It is possible to improve the human condition by clearly defining roles, metrics, and accountability, offering coaching, training, and brainstorming sessions for immediate improvement ideas, and creating standard work instructions. Other human factors include always locating parts close to the changeover area, labeling equipment settings, and eliminating unnecessary motion.

Avoid these SMED-related Pitfalls

Teams should avoid common pitfalls to successfully implement a SMED (definition: Single Minute Exchange of Dies) process program.

- Failure to organize better organization is key to reducing changeover time by at least half. Step three in the implementation process, separating external elements, can reduce changeover times by half. Once you have done that, it is time to get organized.

These external elements should be addressed by your Lean Six Sigma SMED process team. It should be an operator. Someone who is a specialist in setting up. Combination of both? It all depends on the type of activities and processes being used. One person can operate modern presses. Multiple people might be required to perform the tasks if you have older machines.

Effectively organizing the equipment’s surroundings to minimize motion is another way of referring to the organization. This includes organizing storage to make it easier for tools and materials to be found and using point-of-use storage wherever possible. It is important to identify staging areas for dies or other materials and be ready for your next job.

- Do not standardize new processes Inability to standardize new-and-improved changeover processes can lead to highly variable outcomes. This is dependent on who is doing the changeover. A person may be able and quick to set up a setup, but another person might need multiple attempts to do it correctly.

Each person should be able to identify the most efficient sequence of events for each step. The standardization of a changeover should be a group activity that involves everyone. When more than one person is involved in a changeover, standardized procedures are especially important. This coordination is often referred to as “the pit crew ballet”, where multiple jobs are done with precision simultaneously.

- Failure to maintain equipment Research has shown that equipment condition and changeover times are strongly linked. It is much more difficult to set up equipment that has been poorly maintained than the alternative. This is because it will require more skilled or experienced employees, which will make it more difficult to achieve the required accuracy.

To reduce costs, maintenance technicians are often considered overhead. Sometimes, equipment maintenance is prioritized over preventive maintenance. This can lead to a maintenance program that is too risky. It can also have serious consequences for equipment conditions and can cause longer changeover times.

- Avoiding unnecessary equipment investment: Many companies try to increase flexibility by buying new equipment and technology. This is most likely to increase their capacity. It is worth looking into, but it is important to determine if it is necessary.

Consider the skills required to operate new equipment and software. You won’t reap the full benefits of your investment if there isn’t enough training, or the manpower required to operate the equipment.

It is important to remember that not all equipment manufacturers consider SMED when designing assets. This can lead to more complex changeovers, especially when multiple processes are combined into a single line.

SMED Example

I have implemented SMED process (definition: Single Minute Exchange of Dies or Quick Changeover) at several companies in my career as a LEAN and Lean Six Sigma consultant. SMED events are a fantastic way to gain quick ROI to fund an implementation; however, without the infrastructure for and sustainment of LEAN and Six Sigma, these SMED efforts will eventually revert to the old (unimproved) way.

Many of the organizations that I transform have had a previous definition of SMED effort. Typically, I am brought in to Implement LEAN and Six Sigma, which includes reducing Setup or Changeover Time.

As part of our SMED definition event, we have a primer on the first day to cover the purpose of Lean, Six Sigma, and SMED. In class, we discuss what happened during the SMED process event that preceded our company’s (SSDSI’s) efforts.

Most of the time, I hear the same thing. In companies that have cells of machines (or machines in a line or a “U” shape that are dependent on the previous machine), the event members tell me that the previous SMED efforts taught them the tools to speed up their machines. This is beneficial to learn, but they had not been taught how to speed up the cell.

They had not been taught how to think of their cell as a combined entity.

The Lean SMED process education was to reduce the changeover time of their machine. What is missing is the focus on the constraint in the cell setup.

If I reduce the time to set up my machine by 20 minutes (from 40 minutes down to 20 minutes) but another machine that I am dependent on takes 60 minutes to set up, then my net setup time for the whole cell is 60 minutes.

We find in this departmentalized thinking (reducing the setup time of “my” machine), the operator, after finishing his/her setup, starts working on external tasks (tasks that can be done while the machine is running). These tasks are being performed while the cell is not producing.

Six Sigma Development Solutions, Inc. teaches the operator an alternate understanding of Lean Six Sigma SMED process; one where the focus is on reducing the setup time of the cell not just their machine.

They learn to focus on the longest setup in the cell.

They determine before the setup begins what the best “choreographed dance” is that would allow the team to flex (move to another machine) and set up other machines.

This allows them to optimize the capacity of the cell setup so that they can reduce setup time.

This thinking usually reduces setup times by 30-50% without making any other improvements. Once we make improvements to the setup time of each machine, the net setup time of the cell is further reduced.

Do you have a changeover process in your organization that has multiple processes in a line or cell? Have you made an internal effort to reduce setup/changeover time that did not work?

In conclusion

Managers responsible for production should recognize that making what is possible to sell is the best strategy. Six Sigma SMED process allows you to quickly respond to fluctuations in demand.

Defect-free products should be possible from the beginning. It is not a promising idea to rush a setup without knowing when quality products are possible.

A perfect setup change does not require any changes. While some setup changes may be necessary, they should be designed to be done with a single motion. Reducing setup times, reducing lot sizes, and loading simultaneously is crucial.